|

. |

Main Company Profile Page

Based in Sherwood (forest), Oregon (A suburb of Portland)

My Personal Cell # (503) 351-7082 |

|---|

|

Caps |

Roof Caps |

Work |

Gutters |

Parts |

Schedule |

Order Info |

|

My e-mail contact is: |

|||||

|

|

|||||

|

|

|||||

|

This sort of brainstorming solutions happens to be my strong suit, and I love the collaborative process with my clients. Which has fruited me with such a rich and diverse portfolio these days. I can be rather chatty at times, so let me know if you do not want me to talk your ear off about my craft and experiences. Below is an image I created to represent the balance that needs to be reached with each product I design and built for our clients. Not to push what I want to sell. As a highly ethical person my greatest challenge is to design each product with the best blend between these 5 elements for the best long-term benefit to our clients. Those 5 factors do not naturally blend together cohesively. They are more apt to oppose each other. Why use a life-time metal like copper if it is not made to last? I will never build in planned obsolescence! Any product is only as good as it's weakest link, so if the best balance between all 5 factors is not reached, it's simply not a good value. |

|||||

|

|||||

| I am quite passionate about this. I like to approach each project as an artform, which you will find over 10,000 photos showing my step-by-step fabrication process, and unlikely to find elsewhere. In the last few years my project photography has been professional studio quality images. I have 3 high power strobes fire simotaneously triggered by my Nikon D850 camera. You will clearly see this is not just assembly-line work for me. | |||||

|

At CBD, we've primarily made rain management products, but have been contracted to design and fabricate a variety of unique custom copper and copper clad projects that you may have need or just a desire for. We also do some woodworking as well. Mainly for the substructure to fireplace mantles, or building sturdy shipping crates, and such.

I am quite clever to help you come up with unique and innovative solutions to suit your needs. As Copper-By-Design may work a lot in copper of course, but we do utilizing a variety of lasting materials best suited for the different parts of a project. I have thousands of photos on this website and have been uploading my most recent images onto my CBD Facebook Business profile, where people can scroll through those images more easily, comment, like, and share. Click on this link below to see my 150+ photo albums of our more recent projects over the last decade+: I am easily reachable by cell, and open to chat about even small projects with potential clientel. I do not filter my calls through voice-mail, like a lot of businesses do. No automated menues to surf through. Just me; David Rich, cheif designer, salesman, and fabricator. With over 30 years of hands-on experience, so I know what I'm talking about. Not just a slick-talking Saleman. True, perception is everything. No debate there, but I just hate playing such games with people. I try to be a straight shooter. I do not sell what I want to push on my clients. I sell and build what my clients ask for, and may guide them to what will best work for their needs in the long run. I know if I retain the focus of my clients long-term saticefaction, even when un-selling my service, that the money will be there. Isn't this how all businesses should be run?

Copper Material Costs? I have a unique process of repricing a project at the end, once I know exactly how much copper went into a project. Ususally to my client's benefit. I even weigh the copper to come up with a more precise amount used. This level of honesty is unheard of in this industry. Most industried for that matter. If I under-bid a project, I trust you will be willing to compensate me fairly. The same as how you will benefit on projects I may have over-bid, and offer a discounted cost. This way you are not paying for sloppy quotes or even cut-off waste.

This was for my 25 years of dedication to my clients in my contractor business & custom sheet metal shop Rust-Free: The use of steel has been a huge problem in the roofing work industry, yet remails the standard in that industry to this day. Roofers will use cheap painted steel for at least 90% of the roof flashing required. Even with long-life roofing material sold, which is intentional fraud. Any product is only as good as it's weakest link. Even when insisted by the Homeowner to use an iron-free metal, and firmly written in the contract, they will more often still use cheap steel flashing and nails. They act as if there are no other alternatives to steel. Although, all Roofer know steel does not last as long as a low life 25 year roofing material, which in tern voids the shingle warranty. Especially when using a better 35 year, 45 year, or even a life-time roofing material you paid a small fortune for. Yet, you will not get a decent rust free flashing to match? Unless you are there on site to test it with a magnet before it goes up on your roof, you are very likly going to be swindled and cheated out of getting a decent roof job. Only steel or a low-grade stainless-steel will attract a magnet.

From what I know of

steel it is not even worth the effort to install. Even if they sold

steel flashing with a decent automotive quality paint or a powder coat.

Steel flashing or roofing of any sort should be made illegal for

use in the roofing industry, to help minimize our land-fill issue

with so many kilotons of this 'hazardous waste' each year. Yes, that is what asphalt

shingles are listed as. Because of this issue I do

not use cheap steel sheet metal or screws in my work where it would be

exposed to the elements. This is not just the fault of your local Roofer. It has been a Nation wide consorted effort by the roof shingle manufacturers to compel all Roofers to only use steel flashing; by making aluminum or copper flashing very difficult to acquire, besides being more expensive. The roofing suppliers are under strict contract to not stock any aluminum or copper flashing, so those manufacturers will never have to pay out on a warranty claim. Sadly paying more will not get you a rust free flashing in most cases, unless you (a) demand it (b) make sure it's written in the contract (c) and you will also need to inspect the metal before it goes on your house using a strong magnet. I am not exaggerating here. Only steel and low grade stainless steel will attract a magnet. What does this say about most Roofing Contractors who will try to pull one over on their Clients with this intentional fraud?

Germ Killing Benefits of Copper -V-

Stainless Steel:

Lower cost, yet better quality? Is that

really possible?

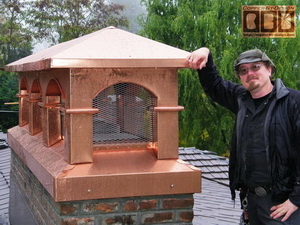

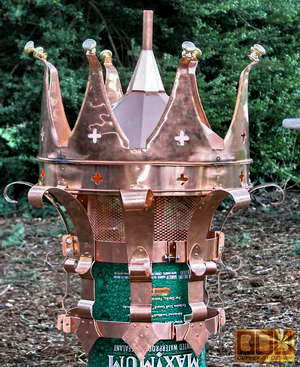

This custom copper work started with a copper gutter client of mine, who had a rusty steel chimney cap, which was falling apart. I had offered to rebuild it for them using copper in stead, so that sort of deterioration would not happen again. Also, knowing copper can handle heat far better than aluminum. I added those photos to my gutter web site: dmr-gutters.com over 20 years ago, and started getting requests from Homeowners across the Nation for chimney caps, turret and gazebo roof peak caps, as well as a variety of other unique projects. Fire pit covers have become a very popular item as well. Eventually I felt the need to author this alternate web site back in 2003 to cater to those Clients specifically. Most of which are out of State. It has grown from there. Replacing gutters is still a lot of what I do, but it is nice to have the chance to be more creative with this in-shop work. Especially in bad weather. I've had dmrgutters.com since 1996. Well before it was common place for small businesses to have a web presence. I've personally spent thousands of hours authoring and updating my business web sites, so please excuse all the typos you'll find here. English was never my strong suit. I was more the art and math geek. Note: We do not intend to be misleading in the pricing shown on these web pages, but as you may have noticed; metal and fuel prices had doubled in 2006. Far beyond any reasonable inflation. Some of the older prices listed on these web pages may not accurately reflect current costs, but also keep in mind most of what you are paying for with this custom work is not the material, but the extensive labor and freight costs for larger projects. You can read more on this subject: Latest News/FAQ Here is another examples of the more interesting projects that I've designed & created from scratch: $14k for this 5X scale Crown style flue (2018)

Then in 2022 we made them a set of 4 matching lamps for their back patio made in that same style. Just half the size. That project ran another $20k delivered. .

$12k for this

1/2 scale Lighthouse style Chimney Cap (2010) Do I need a GC (General Contractor) to work this out with you?  No,

I've been mostly working directly with

Homeowner for at least 90% of these projects. Actually, I've not

had the best experiences working through GCs for several

reasons, but I will if needed. Maybe this will help you understand where I'm coming

from here. I love dealing with Homeowners directly; who have a vested

interest in the

quality of the work I do, and greatly appreciate the extra

effort I put into each project. Homeowners are more willing to wait for their

project to be done right, where GCs just want it done fast and

demand we cut corners to drive costs down. With Homeowners I'm able

to take the time needed to bounce ideas back and

fourth to help improve the outcome for their long term satisfaction. This way there's a better chance to explore options, so

the final results are what suits their needs best. GCS are not

willing to take this time and effort to even convey my concerns with

their Clients, so it has been quite challenging, if not impossible

to work this out with them. No,

I've been mostly working directly with

Homeowner for at least 90% of these projects. Actually, I've not

had the best experiences working through GCs for several

reasons, but I will if needed. Maybe this will help you understand where I'm coming

from here. I love dealing with Homeowners directly; who have a vested

interest in the

quality of the work I do, and greatly appreciate the extra

effort I put into each project. Homeowners are more willing to wait for their

project to be done right, where GCs just want it done fast and

demand we cut corners to drive costs down. With Homeowners I'm able

to take the time needed to bounce ideas back and

fourth to help improve the outcome for their long term satisfaction. This way there's a better chance to explore options, so

the final results are what suits their needs best. GCS are not

willing to take this time and effort to even convey my concerns with

their Clients, so it has been quite challenging, if not impossible

to work this out with them.

Most GCs are not willing to put that much thought and time into this process for you. Their focus is more on speed and lowest cost, regardless of what is sacrificed in the process, so they can maximize their profit margin. Most any GC will do a great job pretending they care deeply about their Clients (such as any other Salesman), yet from the supplier end this simply does not ring true, and I've pretty much lost faith it could ever happen, where they are true to their word. It is far more rewarding for me to work directly with the End-user. There is less lost in communication w/o that middleman who's only looking for cheap shortcuts. So this means less problems arise, and you the Homeowner gets what you wanted (or better) for a fraction of the cost. It's funny how my work seems to offend so many Builders. Compelling them to rip on my work. They vehemently advise against do business with me, because my work makes them look bad in comparison. They may even claim my work is over-kill. My woodwork is pretty much near cabinet quality craftsmanship that far exceeds normal house construction. It's clear my work threatens what they do; crude sloppy workmanship with lower quality parts, yet often charging their clients even more than I do. [as you can tell I do not have much respect for General Contractors]

Do you have

a

crew

of apprentices to help speed up production? Sure, you could say we are Hippies (drug-free) with pie in the sky ideals. My personal attention to design and fabrication of projects should be seen as a plus, but in this world of fast-food service and speedy deliveries from Amazon, many see our slow timeline a deal-breaker, when they had not planned ahead properly. Are you one to appreciate craftsmanship that is not rushed? A project like this will take a whole month of full time work to create. What else does this web site have to offer if I'm not in need of your services at this time? Even if you are not looking to contract with me for a project; you would do well to take time to read over this web site for our ideals on Ethical Responsibility and find valuable advice on the highest standards for gutters, roofing, and roof moss control on the Net. We aim to do what we can to set a good example in the business community; serving to abolish planned obsolescence in all forms, since it is 'intentional fraud'. Which should be a prisonable offense, yet it has been allowed to be standard operating procedure in most industry, which also has more than tripled our pollution and landfill problems. I believe changing this one detail would do more to help the planet than all our recycling efforts combined. We need to pass a law which makes planned obsolescence illegal from this point on. I'm not suggesting the recall of all products already on the shelves. Yet if it can be proven that planned obsolescence was unnecessarily implemented in new products hence fourth a crime was committed. I feel nails are for Neanderthals (there, I've said it). Even the gutters we install are mounted with a pair of #12 stainless steel screws every 2' for an 8X Building Code quality installation on each and every job we do. Visit our DMR Gutter web site to explains these differences in more details.

|

|||||

"Quality and service is not expensive. It's priceless!"

Designed to Last: I know that most of you may read these statements as nothing more than fancy lip-service. Simply 'Too good to be true' sort of thing. Although, if you take the time to read over our web site carefully and see our 9,000+ photos on display you will see we back up these statements with undeniable proof, along with many of our client's reviews. My suppliers say I am the only Contractor in this area that consistently buy the better parts. Also, there are not many businesses that can claim to have received a Business Integrity Award from the Better Business Bureau, let alone 2 years in a row in the late 90's, and again in 2018. Anything is only as good as it's weakest link. Coatings on metal like zinc or high temp paint are not made to last more than a decade or so. I feel that is unacceptable. As a highly ethical person my greatest challenge is to design each products with the best blend between: Aesthetics, Function, Strength, Longevity, and of course made at a reasonable Cost for the best benefit to our Clients. These 5 elements do not naturally blend together cohesively, but are more apt to oppose each other, so my challenge is to reach the best possible balance between each of these important elements. Not to push what I want to sell. As with any product if all of these elements are not well balanced it's not a good product. Why use a life-time metal like copper and high grade non-magnetic stainless steel if it is thin, weak, and dents easily; prone to wind or snow damage? I will never build in planned obsolescence! I passionately feel that planned obsolescence should be made a crime; for the simple fact that it is intentional fraud. Yet it is standard operating procedure in most industry throughout the world (sorry for repeating myself). |

|||||

|

I attributed my success to doing better quality work, at a more reasonable price, along with good communication though this web site, and through e-mail to deal with even small project other shops won't bother with: (A. L. requested not to be named here) |

|||||

|

|||||

Why

Copper? Why

Copper?Copper is the real deal listed on the periodic chart. The reason we proudly use copper sheet-metal over other common rust-free metals like: aluminum, brass, or stainless steel is this: The Classy Earth-tone Look! Copper is the one metal meant to be seen. Like with an investment in gold; copper is a good solid investment in a metal that has long term value, which not subject to inflation like your savings account. It is a sturdy metal that can handle heat well. It also has an antifungal property to it, so virtually no cleaning needed. It is said to be 10X more antimicrobial than stainless steel, so it makes for great counter tops, but not so good for potting plants in where bacteria is needed in the soil. What is the long term look I can expect with copper? Raw copper exposed to the elements will naturally turn brown within a few months, and gradually get darker over time. It normally takes a few decades to turn that chalky green color, unless your house is right on the coast and is subject to salt-air. If you like the 'new penny' look of copper and want to retain that look you could coat it with a lacquer, but you would then loose the natural anti-fungal property of copper. Also, if this is used for the outdoors the plastic coating would get ravaged within a decade or so and begin to look bad; cracking and pealing. It will then of course tarnish between those cracks. It can always be stripped down and polished again, but that kind of defeats the purpose of using a life-time metal like copper that should require little to no maintenance. Copper can be gold-gilded to retain that look, but at $100 per square foot it a rather costly process. I'm told how a century back tarnished copper was thought to be a poor-man's flashing. There is another process called a PVD coating that lasts, but is also expensive. They use a colored chrome plating on the better doorknobs on the market, so it is much more scratch resistant with frequent use.

Cost -V- Value:

Maintenance Free:

Other Sheet Metals Compared (in order

of cost): Steel

is by far the most common sheet-metal

used on roofs for flashing or to cover whole roofs. Only because

Roofing Suppliers across the Nation have made a consorted effort to

make it nearly impossible for local Roofers to get their hands on

aluminum flashing, so they never have to pay out on a claim for the

roofing shingles they sell. I

would like to see it become illegal to use steel for any exterior

application, let alone for roofs, since it

will not last even as long as a low life 25 year shingles, and

causes at least 150% more landfill issues with this hazardous waste than should be

necessary. Steel flashing is the primary cause of roof failure, with

billions wasted each year on premature roofing replacement. This

intentional planned obsolescence supports the oil industry to push

their poison on us. Steel is a

cheap and sturdy metal, but needs painted or galvanized to delay it

from rusting holes through it. Coated steel is commonly known to

develop unsightly rust stains within a decade of exposure to the

elements. That rust show up long before it begins to fall apart, but will

cause permanent stains to everything in close proximity. No matter how cheap steel

is; in the long run steel is actually the most expensive choice when

you consider cost of labor to rebuild and replace it every

15 to 20 years at best. Zinc Aluminum is soft metal, which is why they mix it with other metal to form a superior alloy in most pproducts. Most aluminum alloys are a mixture with copper, magnesium, manganese, silicon, and zinc. If left raw it develops a rather chalky appearance. Most commonly it is painted, so repainting is an issue within a decade or 2, but if not repainted it will still hold water out. Think of how long they have made aluminum ladders with no paint cover at all. The main reasons we had seen aluminum siding vanish from construction and remodeling several decades back is because it lasted too long, so they switched things up to vinyl siding, which has proven not to last well. Aluminum is still a common metal used for gutters, which won't rust. There may health issues to consider when used for food containers causing retardation and such, but that's no a factor for this exterior rain management. Magnesium is a light weight harder metal than aluminum. Often a key component in aluminum alloy mixture to improve it's strength. Although by it's self could be potentially farmable. When ignited there is no putting it out until it is completely burned out. This is what was used in the old flash bulbs cut into fine shavings to burn very bright and fast from a low amperage charge. It is more used as a long-life casting metal, as opposed to a sheet metal. Brass has a nice fools gold look before it has begun to tarnish to a black patina, but it is just a softer version of copper. Brass is made of 70% copper mixed with zinc, which turns the copper yellow to look like a poor man's gold, yet unlike gold it scratches a lot easier. The zinc makes it a softer and a cheaper metal than pure copper, so that is the real reason it is used so much. It is often coated with a fragile lacquer to retain that gold tone look, but will look unsightly within a decade as the lacquer starts to crack and peal from exposure. Stainless Steel is the same cost of copper, but for the same durability you get less thickness, so it is not a better value, and very misleading as to the grade. The modern development of stainless steel as a good strong lasting metal was great, but the bright shiny appearance does not look good on most residential structures (unless you want the look of a retro diner car). Unlike copper, stainless steel will mildew, so there is regular maintenance required. I hear acid rain back East has compromise stainless steel in far less time that copper. In the long run stainless steel is a poor investment and does not add as much to the resale value of a house. Bronze is a harder version of copper. Bronze is also 70% copper mixed as an alloy with silicates to make it harder and less malleable, so it is not useful in this sort of bending and drilling fabrication process. It is largely used as a good long-life casting metal; like expensive sculptures. Titanium actually has been one of the best kept secrets for over the last 200 years +, even though it is one of the most common metal on our planet. Titanium would be an excellent metal for use as a strong light gray look that can handle heat very well, but even though it is one of the most abundant elements on our planet it is still far too expensive to be practical, and very hard for us to machine. Most people have been misled to believe it is a new composite metal like aluminum alloys, but it is actually one of the elements on the periodical chart prior to 1800. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and named by Martin Heinrich Klaproth for the Titans of Greek mythology. If planned obsolescence was not such the standard in industry titanium would be much more widely used, and as a result it would be a lot less expensive. Cars could weigh half what they do now with the same strength and w/o corrosion issues of steel. Such as they do for many aircraft construction. Sterling Silver would be excellent, but far too expensive to be practical for 95% of Homeowners. It will tarnish to a black if left alone, so you would loose that silver look in short order, unless you hire someone to scale your roof and polish it as needed. |

|||||

|

|||||

|

Warning Note: We will work in stainless steel, but since copper cost about the same and is a thicker heavier sheet-metal our clients have preferred the solid 20oz to 32oz copper we use in most of the projects we build. None of the thinner 16oz copper is used in any of our fabrication projects. Yet, that is the standard used in most shops willing to work with copper at all. |

|||||

|

Discussion about

copper

patina, or retaining that new copper penny

look: If we do work it over with chemicals to age the copper this is a very organic process and turns out different each time, so I cannot guarantee what we acheived will be just what you wanted. We cannot afford to keep polishing it again to redo that treatment several times in order to get just the look you're after. Besides the fact that photos may not propperly represent the look it has when seen in person, but most of our Clients are out of State, so that is not an option.

Here's a link to a chart for different copper

patinas: |

|||||

|

..David Rich with a large circular turret roof cap

Long Term Value

(if built well): A lot of thought is also put into designing an easy installation as well, so I even supply the stainless steel fasteners needed, along with personalized detailed installation instructions. I may be a bit eccentric with all this, but it has been found that using copper sheet metal is the best long term and short term value. Please, let me explain: We all know how the cost of 3 or 4 replacements would be far more expensive than 1 quality product, but we often do not have the resources to do projects right the first time. There has been a long standing dilemma in the roofing industry with the use of very thin 16oz copper typically used. It seems to me illogical to have a product made with a long life metals like copper if it is just made so thin and fragile to save on cost. It will just end up looking dented or even fall apart within a few decades anyway, so why bother. In that case steel would last nearly as long and be a fraction of the cost for the material. If built well copper would last well over a century, but this is very rare to find because of the added cost of materials and the ignorance of most people to these issues. That is why steel has long been the standard in roofing Nation wide, since it is strong and a far more economical initial investment. Although, as a short term investment the use of copper usually would increase the resale value of a property more than the cost difference of using a cheaper material, so it is actually profitable from a realestate issue. |

|||||

|

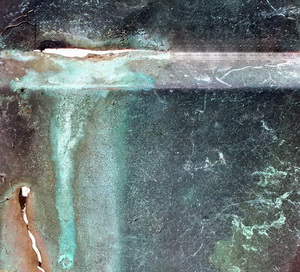

Just like with the auto industry, where the use of steel remain the standard for over half a century. Long after the advent of aluminum. Although, I imagine you expect to keep these rain management products in service with little to no maintenance a lot longer than your car. It would be very costly to hire a detailer to scale your roof to clean and wax painted steel covers and flashing a couple times each year, but if left unattended they will cause ugly rust stains long before they begin to form holes and fall apart like many of the roof caps I've replaced (shown above). Again, if built well copper products will not need maintenance or even cleaning. The custom labor, shipping, and installation cost that go into any of these projects account for well over 75% of the cost, so it is unwise to use a cheaper metal that will not hold up. Some reports will suggest that copper is only good for 50 to 60 years, but I also know that is based on standard 16oz copper. Thinner copper like that is only used to help minimize cost, so most sheet metal shops will use a very thin 12oz or 16oz copper, which will actually wear holes through it in that time-line (as seen in these photos below) and the soldered seams will crack apart. Water may not seem abrasive to the touch, but it has been known to wear down mountain given enough time. If it is not made well with sturdy materials then using copper is a moot point if it is just going to look all dented and fall apart. I have saved this thin copper scupper as an example to remind me what I work to avoid. |

|||||

..

|

|||||

|

.. |

|||||

|

Short Term Value: |

|||||

|

.. |

|||||

| .... | |||||

|

..

|

|||||

Tia and David Rich (New Years Eve party 06) |

Who is Copper-By-Design? |

||||

|

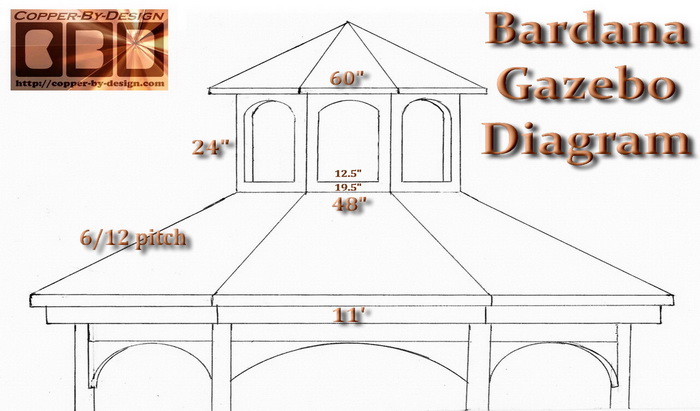

We are located in Sherwood, Oregon just a little South of Portland. Besides being self proclaimed (drug free) hippies with a profound compassion for those we do not even know (see: mind-temple.com), I also seem to have a unique aptitude for mechanical comprehension and spatial arrangement, which help immensely to visualize, design, and create these unique 3-D projects out of flat sheet of copper sheet metal. I've recognized the need for these custom products for clients across the Nation like: decorative turrets and gazebo roof caps, roof ridge caps for moss control, chimney caps & flue covers, scuppers or leader heads, water features, along with an assortment of other original designed and personally fabricated products. |

|||||

|

This growing work had inspired us to develop this alternate web site to my local gutter work in order to reach clients through the Internet. These days over half our gutter clients contact us on-line, and around 80% of the custom copper work is for out of State clientel. I had first published my web site for the gutter business back in 1996 under https://dmr-gutters.com, but at that time the web address on the side of my work vehicle got more attention than the actual web site. Over the last decade this has gradually changed to the point that our web site is now more beneficial to our gutter replacement sales than even referrals. I've now published over 10,000 photos and put thousands of hours into it's development over the last 2 decades. Homeowners have become a lot more web savvy. More and more people are carefully researching the web to find something better than just the normal contractors who talk a fancy jargon, but only deliver a fraction of what they promised. Looking in the local phone directories just wasn't cutting it, so Homeowners have been networking on-line through websites. I struggle to find the best quality parts available at a reasonable cost, yet sadly our suppliers report that I seem to be the only contractor in our area who consistently buys the better materials, so it is not profitable to stock them for just one client. It seems to be true; as I have not personally met a decent roofing or gutter contractors in our local area. We stand behind our quality with our extensive warranty (see: our Warranty & Service web page for details). There's a 20 year manufacturing warranty on the copper products we sell. The only reason I do not offer a longer warranty is that it would be unrealistic and would insult your intelligence to offer more. Where will I be more than 15 years from now at the ripe age of 70+? What are Our Qualifications? Besides my high standards and ethics, I (David) had been tested in High School to have an unusually high aptitude for spatial arrangement, art, math, along with a 99% mechanical aptitude, which I was told was the highest score possible and quite uncommon, so they needed to figure out how I must have cheated that test. It takes these sort of abilities to visualize and diagram new original designs for fabrication, and make sure it will be strong to last over the next century, easy to install, as well as attractive. I strive to place a lot of focus on strength and function. If built well; it should be able to last well over 100 years and be reused each time re-roofing is needed. That is why we supply the stainless steel screws along with a new #3 Phillips tip to do the installation with, so it can be a cherished heirloom. I honestly seek to raise the bar, after seeing what commonly fails in construction over the last few decades. I would not want anyone to work on my house who's only hope is the parts to last a year trouble free: just enough to avoid their liability. About 30 years ago, this was the motivation that inspired me to go into construction, after needing to figure out how to do everything on my own. Schooling was useless, since their primary focus was how to get jobs that can be done fast and cheap, so they would maximize profitability for contractors to financially succeed. I am personally diligent to respond to client e-mail within 24 hours, but it can take as much as a dozen hours of my time to get all the details ironed out over the course of several weeks of correspondence with a new client on just a small one time project. That is depending on how fast the client responds back with the info I need. Then several more hours to design, fabricate, box up, and ship a simple $200 roof cap. I was highly interested in art since third

grade. At 17 I got my first professional contract to make a life-size

Darth Vader

for the promotions of Empire Strikes Back (first

release) with working LEDs in the

belt units and a lit light saber. All built on a shoe-string budget

of only $300. One of my artistic passions is authoring these

hundreds of web pages, but most notably is how I am the primary designer and

fabricator of the copper work you see here. One reason that I have these talents is my Grandfather (John William Rich) who was a brilliant inventor of several well known products, but most known for his Rich's Frozen Food Program back East, and his TV chairs seen at large airports and bus terminals. But his greatest invention was the development of the Rich's Safety Bumper for cars and City busses made of a large hollow rubber cell filled with water for the low-tech hydraulic absorption of the impact. It made driving like playing bumper cars; with his 15 mph no damage bumpers, affording drivers a 20% discount off their auto insurance. He stepped on the toes of the major auto makers here in the USA and his company was crushed like an annoying bug. You can read more about it on our Ethics web page. Tia has demonstrated a talent in artistic design and has assisted in designing these web pages since early 2000 and helps proof read them. She also consult in design ideas for copper work and helps in the shop. Tia's Father worked on the robotics of the Disney rides in California, and her Mother was very involved with crafts and paintings. This attention to detail and reliable service has earned us a spot as finalist 2 years in a row for the BBB Business Integrity Award (shown below). What about contacting you and good swift communication? We have been told by numerous clients that in

searching the web for this sort of information; we clearly have the

most comprehensive web site on custom copper sheet metal design and

fabrication in the world, with our 300+ web pages and over 4,000 photos,

that link to full screen digital images for a better look at our work

with prices listed of what they had paid at that time. You are likely to agree.

Some people feel we We feel there are already hoards of simple web sites that you could navigate and read over within a few minutes, but that is not the grouping we want to compete with. We virtually stand alone here on the web for an on-line store front for a small business like ours. If nothing else this web

site shows our commitment to good clear communication, which is very

important to us. I am personally careful to check e-mail at least twice a

day, and respond within 24 hours. If you had not heard back from me

with a personalized reply within

that time, call me to check if I received your e-mail. I

answer calls personally, but I do not quote projects

over the phone for a couple reasons: We specialize in custom copper designs. We rarely get a chance to reuse a pattern or template a second time, since each clients needs have been uniquely different. We actually encourage unique designs, as opposed to pushing clients over to generic designs by offering discounts. The only discounts we offer are for clients who have carefully read through our web site and have provided us with all the info we need to provide a quote in the first e-mail exchange. There is also a volume discount, but that rarely happens. |

|||||

|

.. |

|||||

|

|

|||||

|

.. |

|||||

|

Why is quality and craftsmanship so hard to find these

days? Ethics and integrity are words with a powerful meaning, but seems to have lost much of it's relevance these days, like the words: super turbo charged, titanium, or platinum cards. We have been told by many clients how our prices are quite reasonable and even lower than many other shops. Being a small hands-on business I have a low overhead compared to most shops. I'm still just a humble low-life 'renter' myself. That makes our swift production capability much more limited though. If some of the prices listed on this web site seem a little high, try to keep in mind that many of these items are shown with the priced including the cost of a strong wood custom made crate with shipping charges, unlike you'll see elsewhere. We do not play the game of showing you a lower price, and then tack on a huge shipping and handling charge. If you happen to be local enough to drive here to pick up the fabrication we will gladly discount those costs of course, which could save you over $1k. I am often using more copper than estimated, yet will stick to my quoted price. Copper is gauged as weight per square foot for sheet-metal. When it is shown gauged any other way there is a good chance it is only painted or copper plated steel, so beware of this sort of scam. To minimize the costs and be easier to work with most fabrication shops use 12oz or 16oz copper. We use 20oz copper or thicker for our custom fabrications, so they are heavier and more dent resistant, and less prone to wind and debris damage. Thicker copper like 24oz, 32oz, and 48oz is of course more costly and harder to work with, so that greatly raises the cost, but I price it at the same cost per pound as the 20oz copper, so it is usually $20 #.. |

|||||

|

. |

|||||

|

. |

|||||

|

What if you

are not local to us? I would say well over half of our work over the last few years has been making unique custom copper sheet-metal products for clients back East, a few in Canada, and 1 in the Caribbean. We have been filling orders for a variety of uses, like: chimney caps, gazebo & turret roof peak caps, scuppers, water features, and such. Turret and gazebo roof caps had been our most popular items, but requests for custom chimney caps have steadily risen to overshadow roof peak caps. I'm happy to talk with you on the phone, but please go to our contact info page and read it before calling me, since I may be up on a 2 story ladder with a 40' gutter in my hands when you call. |

|||||

|

|

Installation:

I am not able to work legally outside Oregon State and do not carry the liability insurance to do roofing related work, so ironically I am not able to install these roof caps even locally. There is no network for us to find and refer you to a good local roofing contractor. Although, if you are searching for a reliable contractor, this web site is one of the most comprehensive and honest web sites on gutters, roofing, Moss Control, and Roof Treatment. You should find the information here very helpful to better know what questions to ask of your local contractors. Helping you better able to weed out the less reputable contractors, to find one that you can hopefully rely on. And in so doing you should save a lot of money and future head aches. For a good honest resource to find reliable contractors in your area that your neighbors have used and reviewed: |

||||

|

If you are not able to do the

installation yourself; I wish you good fortune finding a reliable

contractor in your area. If you are able to find a contractor that you feel

comfortable with, have them look over our website here to see just

how we do our installations and have them contact me with any questions.

If they claim they completely understand just what to do already, that

is probably not a good sign. |

|||||

|

Custom Chimney Caps and flue extensions from $200 to $12k Custom

4, 5, 6, 7, 8, 10, 11, 12, & 16 sided Roof Caps Custom

decorative

Scuppers Custom Range Hoods and Mantles Other custom Sheet Metal Fabrications Retail seller

of inexpensive Cupolas,

Weathervanes, Non-local Supplies of special custom aluminum and copper sheet metal gutter parts Rust-free Gutter Replacement |

|||||

|

.

|

|||||

. |

Our

Personal Thought on Ethics |

|

|

The next statement is a simple concept that is un-debatable (we dare anyone to try), which doesn't require a subscription to any particular dogma. It is simply logic. These are words we strive to live by. Why is this not being taught in our Schools, let alone a strong philosophy in the business world? Planned obsolescence should be a crime, yet it's a standard in most industry through out the world. What a sad state of affairs. |

||

|

Setting a good example is the only thing we

truly have control over, and the best we can hope to accomplish

within our life. Unless we are honorable with those of our

association; be it business and or personal, we have no right to

even hope for any better from others, let alone expect it. We each

need to strive to create the world we would hope to live in,

regardless of what we may get in return, as an absolute rule without

waiver. I imagine you or anyone you'll ever meet could not honestly say "I don't mind living in a world of lies and deceit", so the least we can do is not add to that muck from what we put out there as to our words and actions. Even when no one's looking. We also need to accept how others have just as much right to live and prosper as we do; unconditionally! Others are not be cheated through our selfishness. Beside unjustified WAR, this is manifested in many more ways than you could possibly imagine; in how we conduct our daily life and purchases. Please take some time to research 'Fair Trade'. I wish Ethical Responsibility were not such a rare quality in our modern business world, but wishing and waiting on the side lines is not going to help. The best any of us can truly hope to accomplish in one's life-time is to set a good example in every aspect of what I do; to show it is possible to still make a modest living while running an ethical business. My ideals are not because I was raised a Mormon in Utah. I have not found the LDS share my passion for ethics, let alone implement it in their actions beyond their pretenses, or else it would have impacted the business world a great deal more than it has through fair competition. Don't be just a clich'e hypocrite. I can only hope to inspire others to seek out opportunities for good karma to enhance their lives and character through helping to enhance other people's lives in their chosen field of work with compassion and care. Every aspect of all we do should be approached as an art-form with conscious intention. We can try to teach others how to live and love, but until they own it and becomes a part of them this sort of philosophy will just be a pretty string of words with little real meaning. As long as we strive to set a good example perhaps those around you will eventually gleam wisdom from your example. You can not force it on others, and we need to be very patient, as they still need to grok it within their own time-line, or perhaps the next. author: David Rich |

Read much more of our thoughts on 'Ethical Responsibility'. |

| . |

| Note: We hope that we can be mutually beneficial, but if not there is still a lot of helpful information here on these web pages on dozens of different topics. If you find the information here very helpful, but you are not in need of our services, it would be kind of you to show your appreciation for the generous advice we spent thousands of hours to provide here for your benefit. Perhaps like you would tip a waiter. Maybe this information is worth enough for you to send us a nice gift certificate of a dinner for two at a restaurant local to the Portland Oregon area? A favorite of ours is Oswego Grill, but even something at Burger King would be nice. Don't feel too bad if you are not feeling that generous, as we have rarely had someone actually send us a gift. I'm just providing an opportunity for you to benefit from good karma ;) |

..

|

Below is a photo of our Better Business Bureau's NW Business Integrity Award we earned for the year 1998 |

|

We were also a 1997 & 2018 finalist for this same award. See our referral web page to see how we managed to be honored with this special award |

.

.

|

"Quality and service is

not expensive, |

|

dba: Copper-By-Design Sherwood, Oregon |

A fan made video of our photos from our portfolio

|

Caps |

Roof Caps |

Work |

Downspouts |

Parts & Info |

Ordering Info |

.

.

.