|

Cell Phone # |

Decorative

Custom

Funnels

for downspout applications Also called: Updated 12 / 2022 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Company Profile |

|

Roof Caps |

|

Chimney Caps |

|

Scuppers |

|

Gutters |

|

Shipping |

|

Contact Info |

|

Introduction & Information About These Decorative Funnels |

|

|

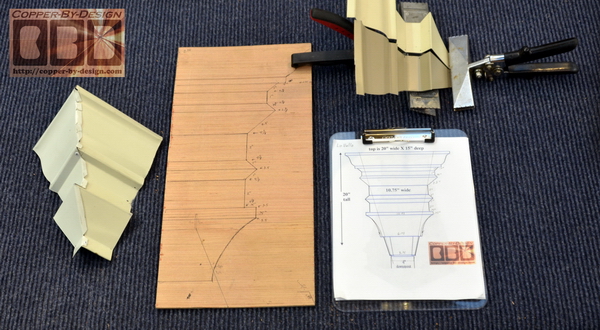

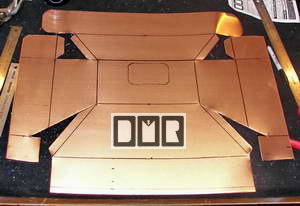

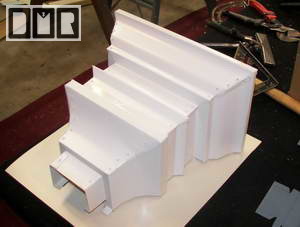

There are dozens of different uses for scuppers in residential and commercial roof applications. Which also means hundreds of different shapes and sizes needed for each project. Far too many different needs for a company to make in a few common size, metal type, and color in order to stock quantities of them to order off the shelf, so CBD makes each project to order. We have none of these in stock ready to ship, but simple units can usually be done in a couple hours and shipped within a week. Where some more decorative scuppers can take a full week just to make. My primary work has been residential gutters and downspout replacement for the last 3 decades with custom durable rust-free sheet metal rain management products. These are just fancy custom funnels used to enhance the looks and improve functionality of a roof drain system to avoid a back-up of rain water over the roof if this transition were to clog up. Which it will, since most people do not maintain these as often as they should. Not until they see a problem develop. Although, it is more common to see these installed wrong; mounted too high in order to cover the hole in the parapet wall from street view. This can and most likely will cause very serious roof damage and even a collapsed roof, which would be devastating. This is very common mistake installers will do for aesthetic reasons, since it is not usually raining when they are installing them, so it does not occur to them what would happen when this plugs up, which it will. It is imperative that the upper rim of the scupper is mounted below the roof surface, so when it backs up, it will just over flow off the outer rim and dribble down. Outside of the roof drain. Many Roofing Contractors will argue this issue, but there really should be no debate on this at all! It should be a simple matter of common sense. A metal shroud or wood shroud can be mounted over the scupper to hide the roof drain hole if that is an aesthetic issue. Such as shown in these images below: Most of the scuppers shown here on this page are not just a simple 'V' shape funnel that you may have seen other Gutter Contractors use. Typically made with just cheap steel and do not have a liner that CBD implement in our best designs. Here is an example of an aluminum mock-up we often have to make before building the copper units, so we are sure to have all the dimensions and bends worked out first. This has been a dead art for over half a century. It will take me a full days work or more (w/o interruption) just to build 1 of these decorative scuppers. That does not take into consideration the many hours spent working out the details with my Clients through e-mails and phone calls, taking photos, and processing them to share with our clients before the units ship, and then getting them securely boxed up and delivered to the shipper, so these cost a bit more than just a simple mass produced funnel. These can range from as little as $30 each for a simple aluminum funnel with an upper rim (as seen above in dark brown) or up to $1k each (below right) depending on the size and complexity.   From the most simple to the more ornate profile options These designs can also be made to fit an inside or outside corner application, so please specify when ordering Many sheet-metal shops across the country make simple generic sized 'V' shaped painted steel or aluminum funnels that will certainly do the job in most cases, but they tend to have a rather small outlet at the bottom, which will clog easily. I could make those as well, but I pride myself as a custom coppersmith with an artistic edge to make these type of above standard scuppers. Making products that are better than standard is my mission statement. I place a lot of my focus on durability as well. Even over aesthetic concerns. CBD uses a minimum of 20oz copper, in stead of the thinner 16oz copper, which is the standard at most shops. So, built with a liner that is a total of 40oz copper per square foot between the inside to the outside surface. I work hard to design them as seamless as possible even when it's not a practical use of the copper sheets. There's little point to put this much effort into one of these scuppers if it's just going to wear out or look haggard within a decades or so by using that thinner copper. They might as well be just made with steel in that case when it's not made more durable to last. Keep in mind how most of what you are paying for is the labor and freight, so using a thicker copper is not that much more expensive. Here is a comparison to consider: 16oz -V- 20oz: 25% thicker, yet 50%

stronger Most any other copper scuppers I've seen were made with just a paper thin 12oz to 16oz copper sheet metal to reduce cost and easier to work with to cut and bend into shape, so there's less of a Client sticker shock. Although, they will fail before long. I used a thicker 32oz copper on this set of scuppers seen here below right for support without the need for a wood structure underneath.

CBD is not the fastest fabricator for large orders, but if you care about lasting quality and personal service we are well worth the wait. Here's a link to our Latest News page for my time-line and my Contact web page for requesting a quote. |

|

|

Why so few craftsmen left? It seems there are not a lot of talented sheet-metal fabricators promoting their work on the web, such as this, with good clear photos and prices to comparison shop. Or at least willing to correspond through e-mail with photos and diagrams needed for small projects like these. It is not uncommon for me to respond with a dozen e-mails to work out these details. It takes a good deal of care, and swift attention. To work this out takes good prompt friendly communication skills and discipline few seem to have. To do good custom work like this requires good geometry skills, imagination, and a high mechanical comprehension. Diagrams and digital photos have to be passed in order to work out crucial details, so this will work out just right without complication. Few shops are willing to invest that kind of personal attention and ask the right questions unless it's for a large development project where a hundred units are being ordered. |

Here's an

old ornate copper scupper I This was beautifully designed and fabricated with precision. Although, it was made with a thin 16oz copper, which had holes worn through the left side wall, and the solder joints had started to crack apart in several places w/o any signs of an impact. |

|

What are your qualifications? |

|

|

Why I do this?

I'm careful to respond to each e-mail within 24 hours, but it may take over 8 hours of my time just to get all the details worked out over several weeks, depending on how fast the client responds back with the info I need. Then several more hours to design and fabricate even a $200 scupper (minimum charge for custom orders). This has to be a work of passion, since it is not making a lot of money. PS: I recommend against using round downspouts for several reasons as listed on my Downspout Comparison web page |

|

|

What metal is best

for these decorative funnels? Lead: is a thick soft easy to work with metal that can be cut with just a pair of scissors and shaped with bare hands. It can be custom shaped right on the roof peak without any special tools, so many building contractors like this option best, but of course it is not very durable for use as a scupper and hard to seal the seams well. Copper: is clearly the best option here. It is a metal that is meant to be seen. It will tarnish within a few months to a satin brown. It actually takes nearly half a century to turn that chalky green depending on where you live. This dark earth-tone look makes copper a lot more appealing to most people. It will also stay clean, since it will not mildew. The cost difference of cheaper metals is marginal with this sort of custom work, since it is typically only 10% of the cost for custom fabrications like this. To help minimize cost; the standard in the industry is 12oz or 16oz copper. The thicker 20oz copper I use for custom work is very good for archival quality to last for well over a century, unlike the old scupper shown above. It is sturdier, which is more dent resistant as well. Warning: Other sheet-metal shops may say they use copper, but it usually is only a very thin sheet copper, or worse: only copper plated or painted steel. Solid copper will not attract a magnet, so it is easy to test for this deception, although it may be too late by the time you have it in your hands to test this. Copper thickness is different that steel gauges. It goes by weight per square foot. If they say it is 26 gauge, that may mean it is only copper plated steel, and still very thin. The 20oz copper we use is about twice that thick. Stainless steel: is a good strong metal that will last, but it remains that shinny mirror-like finish until it mildews. Since it is about the same cost of copper, with out any anti-fungal properties, it is rarely requested, but strongly pushed by other sheet-metal shops for reasons listed below. Warning: Other shops will push stainless steel like it was the best thing on Earth. Especially for chimney caps. That is because stainless steel is quick to fabricate, since it can be simply spot welded together. They also do not need to worry about finger print oils making the metal surface tarnish irregularly. You need to beware: they will talk about stainless steel, but actually substitute with galvanized steel to unsuspecting consumers, since that client will not see it start to rust for about a decade later. Well past most warranties. Or parts of it will not be stainless steel like the screen or the bolts. You can test this with a magnet. Good stainless steel will not attract a magnet.

Galvalum: is better than galvanized steel and stronger than aluminum, but again it is not worth the minor cost difference of copper when most of what you would be paying for is labor and freight, so we do not even offer it as an option. Steel: is a strong cheap metal, but it will rust through far too soon to be practical and cause rust stains below if not replace before this happens. Besides, the savings to you is marginal, since most of the cost of custom work like this is the labor and shipping. It would save you less than 10% off the cost of using the thicker 20oz copper we use. I do not even offer steel as an option, because it goes against my ethics. |

|

Delivery

& Installation? Delivery

& Installation?I work hard to design these scuppers to be sturdy, easy to install and re-install easily with the stainless steel screws provided when re-painting the house or other service required. I would be happy to install the scuppers for you if you happen to live local to the Portland Oregon Metro area, but I've been getting most of these orders from Clients across the Nation through this Internet exposure. If you are not close to us and you are not able to install them yourself, you will need to hire a local Contractor to do the installation, since I am not licensed to work outside Oregon. Over the last few years I've been successfully shipping custom copper works in large custom wood crates to clients in all corners of the continental USA and a few in Canada. Through the fabrication process I will send you digital photos of the progress I've made through e-mail before shipping, and I welcome your feedback. |

|

.

| A few Design Options and Cost Examples to Consider | |

|

We do not stock any of these in anticipation of an order. They are only made to order. We are happy to customize these to your needs. We have a $200 minimum charge for any custom work like this, which runs $60 per square foot of copper used for the outer shell based on the final weight. The copper liners are $25 sq'. I highly recommend (if not insist) these have liners for better function and durability, which oddly is a detail you're not likely to get from any other fabricator. I offer discounts for volume orders over 10 units of the same size and design. |

|

|

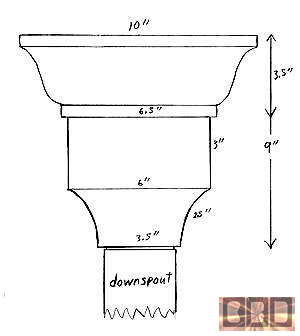

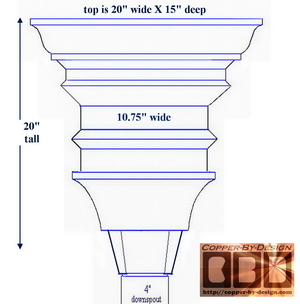

Style #1 Drawn-up for a client in Tampa Florida (2-04) |

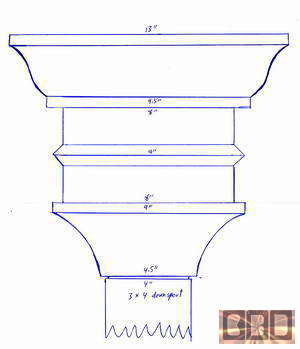

Style #2 Originally for a client in Salem Oregon (2-04) |

|

Diagrams #2, #3, and #4 have a little more ornamentation added to center. If you have a different idea of how you would like it shaped or what size you need, feel free to write us an e-mail, including any digital diagrams or photos that may show us what you have in mind, so that we can better quote you a price to get you just what you want. We can form curved surfaces, but that does add to the cost. |

|

|

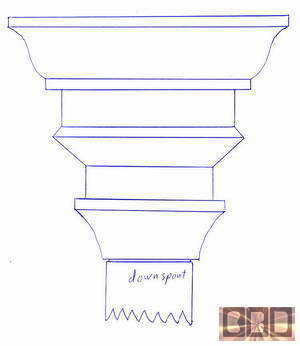

Style #3 |

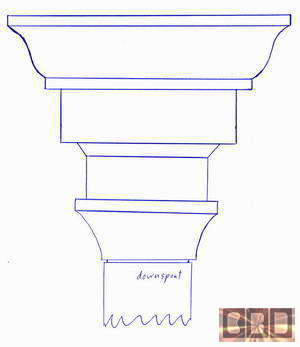

Style #4 |

|

Style #5 |

Style #6 |

.

|

Some different

variation of

scuppers I've made |

|

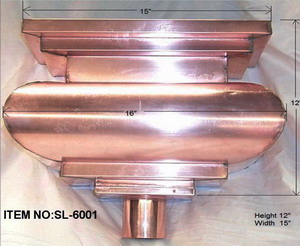

Our 5 Facet

Funnel / Scupper: Our 5 Facet

Funnel / Scupper:A simple design for flat roof outlets, or a more decorative funnel to join 2 downspouts into one. This has an internal rim bent over the top edge for added strength and a clean look. Measurements for 2X3 DSP: 8.5" wide, 5.5" deep, 13" tall Measurements for 3X4 DSP: 12" wide, 8" deep, 12" tall Made in 20oz copper or 30 different colors in a pre-painted aluminum. The prices for these are found on our Shipping web page: http://copper-by-design.com/ship.htm#Scupper For an extra cost this could be made with an outer rim squared off or using a copper pipe. What ever you want or need. |

|

|

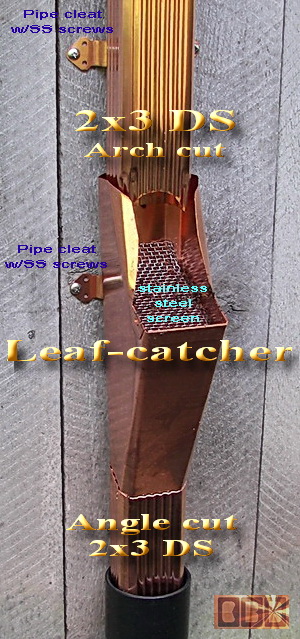

3.25" X 10" Super Outlet A common misconception is the size of your gutter matters most. It really matter less how big your gutters are. If the outlet is still the same small size it will clog just as quickly, so it matters more how larger the outlet is more than the size of the gutter. With a larger outlet the debris can make that transition into the downspout and can be caught in the Leaf-catcher down where you can reach. This way the gutter will continue to function. This 10" wide custom outlet w/3X4 reducer to a standard 2X3 DSP installed added $80 to the cost of each outlet of this copper gutter system. These Super Outlets are also very useful under a split gutter for use as an expansion joint to relieve tension off the corner joints for long runs over 40'. |

3X4 to 2X3

Reducers I have designed several templates to form adapters in copper or painted aluminum. This assembly converted about 24 cubic inch displacement of these 2 gutter outlets down to just 6 cubic inches for a standard 2X3 DSP vertical drop with little risk of a clog. For these 2 reducers and funnel installed added $160, but used less copper DSP by combining these 2 downspouts and only needing one Leaf-catcher below (not seen here). |

|

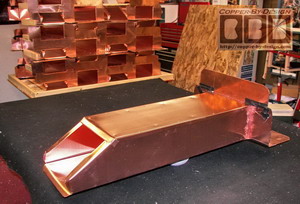

This is a custom aluminum catcher basin to catch the rain water from a narrow valley. It was made from a short straight gutter, with each end mitered, instead of just slapping on a pair of end-caps. We flattened the back side to make the bottom a bit wider and made a new higher back side. It has a 3.5" x 4.5" funnel mounted in the bottom as the outlet, reducing into a standard size downspout. There is a double 'A' offset elbow right under it to divert the rain water back to the downspout on the siding. This sort of scupper runs only about $200 in aluminum, or $300 in 20oz copper plus freight. We didn't need to go to this trouble, but it just makes it look a little nicer, without going to too much effort, like the more decorate scuppers we make. |

|

|

Super Outlet Tray In stead of using common elbows under this split copper gutter expansion joint, I made this custom scupper or tray that narrows from 9" down to 5" wide at the house with a reducer installed at the back priced at $35 sq' of 20oz copper used to make this. They are open at the top to be able to clear it out when needed without requiring tools. |

A 10" Wide #1 Style Scupper

This scupper was a set of 3.

The cost was $248 each installed in 2008. Here is a link to see more

pictures of how these are fabricated: |

|

Brodsky Inside Corner Scuppers |

|

|

I first made them a set of these basic aluminum scuppers as a temporary fit, while they waited over a year to have me make these better copper units. These temporary scuppers are better than what most contractors would install. I put a stainless steel woven screen inside to filter the debris, which has a 2X2 weave per inch, where the leaf-catcher screen in the downspout has a finer 6X6 weave. To see all 100 photos and read more about this project go to: https://www.facebook.com/media/set/?set=a.2185067154900627&type=3 |

|

|

Super Dupper Outlet Tray |

|

|

The extra cost for something like this in aluminum would be around $650 installed for the 4' of gutter: $30, + 4 corners mitered: $240, + installing this large funnel/tray under it: $260, + the extra large funnel under the tray: $120. |

|

|

Maximum Headroom with No Elbows Outlet Tray |

|

|

We had charged about $200 extra for this custom scuppers, instead of normal downspouts. |

|

|

Other Corner Scuppers |

|

| Most any design shape can be custom formed into an inside or outside corner basin. These are just a few examples: | |

|

This small corner scupper was just 9" wide, but can be made in any size or shell design shape. This is just one example. Note: I recommend against these round downspouts for several reasons, as listed on our Downspout Comparison web page. |

|

|

A Common Gutter Made Into a Corner Scupper w/mitered ends: The current cost for this in aluminum was calculated from the basic cost of the gutter needed to make this at 3 ln' X $5 = $15, + $60 for the cost of mitering 1 corners + $120 to miter the 2 ends + $60 for installing this funnel in the bottom = $255 total installed. |

|

|

Keep in mind most any scupper design shown on this web page can also be formed into these sort of corner scuppers as well. |

|

|

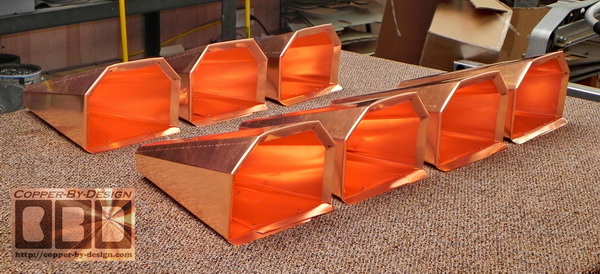

Designs #2, #4, & #2/3 combo made in 20oz copper w/liners |

|

Click on the image above to see the step-by-step fabrication of that scupper. The photo to the right shows a combination of design #2 and #3 made 20" wide for a Client in Grand Island, New York at the cost of $500 each X 8 units shipped inside the same crate as the chimney caps we also built for them. |

|

|

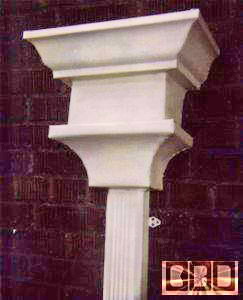

Here was a set of 4 custom white painted aluminum 14" wide scuppers I made for a client here in Portland Oregon in late 2007 for $300 each installed:

To see and read more about this project and see all 40 photos

go to: |

|

|

A Large 39" wide

Scupper - $500 delivered to The Hamptons, NY

back in 2005 |

|

|

You can click on the photos here to go to the design and fabrication web page for this leader-box where you will see many more photos of it's design and construction. To see and read more about

this project go to: |

|

|

Fancy 5 sided 14"W Scupper Recreations - $500 each installed back in 2008 |

|

|

See more at: http://copper-by-design.com/cw/TaraNorth.htm |

|

|

My First Fancy Scuppers Made in White Painted Aluminum (1996) |

|

|

This scupper funnels into a standard 2"x 3" downspout. It is about 14" across the top, and sticks out about 7" from the brick wall. The lower rim is about 9.5" wide. We do not work much in aluminum any more when this sort of labor is involved, since copper would only add $10 to $20 to the cost, it seems silly to invest all that effort into an aluminum scuppers that would dent a lot easier and is prone to scratching and general paint failure. Copper has been the preferred choice of most clients, but that also means you will need to have copper downspouts as well, which increases the cost of your project a good deal. |

|

.

| Other Types of Built-in Scuppers for Flat Roofs and Valleys |

|

The Auerbach Roof

Drain Channels

(4/09) |

|

This set of 2 decorative diverter trays I made out of a thicker 48oz copper to hold a set of rain-cups without the need for a wood support underneath. They were ordered through SYMBIOS, a contractor in Occidental, California for their client. They made this cardboard full size model and sent it to me to work from, so it would be sure to fit just right. The total for these two custom scuppers was $450 with shipping.

To see and read more about this project and see all 9 photos go to: |

|

The 24 Mahaffy

House Roof

Drains

(8/06) |

|

These built-in scupper roof drains were made for Kevin Mahaffy. We passed around 50 e-mails w/diagrams back and fourth over the course of 7 months to work out all the details of this order for these custom products; going over size, shape, and metal thickness (am not one to rush a client). I sent him samples of copper to feel. He ended up going with a thicker 32oz copper for the bottom and sides for added strength, so no wood structure needed to be made underneath for support. The top cover and upper flange was made with just the 20oz copper I normally use. The total for these 24 custom scuppers was $5,808 delivered, which is just $242 each.

To see and read more about this project and see all 21 photos go to: |

|

The Mitchell

Front Entry Roof

Drains

(7/05) |

|

These built in scuppers along with some decorative fascia board covers were for John Mitchell. We wound up passing about 40 some odd e-mails and several diagrams back and fourth over the course of about two months to work out all the details of this order for his entry roof he was building. This total for these two custom scuppers was $385

To see and read more about this project and see all 51 photos go to: |

|

The Stevenson House

Roof Drains

(11/07) |

|

She had me replace 2 built-in scuppers seen here, so they would last beyond the 50 year roofing. The last repairman had covered the rusty steel with aluminum foil (used for cooking) as a fix to keep it from leaking into the house walls, so of course that did not work. I could not believe my eyes when I saw it! By that point the rust holes under that foil were large enough to pass my fist through.

To see and read more about this project and see all 40 photos go to: |

|

This is a custom aluminum scupper we fabricated for a customer who has an unusual situation for a drain on a flat roof. We took the rusted steel sample he brought to me to build this from. It had some very special angles to it as you can see. There is a blue square 5 gallon bucket just behind it to show some dimensions to this scupper. The old rusty scupper is sitting on the blue bucket. Here it is from a different angle. You can see the rust on the old scupper |

.

.

|

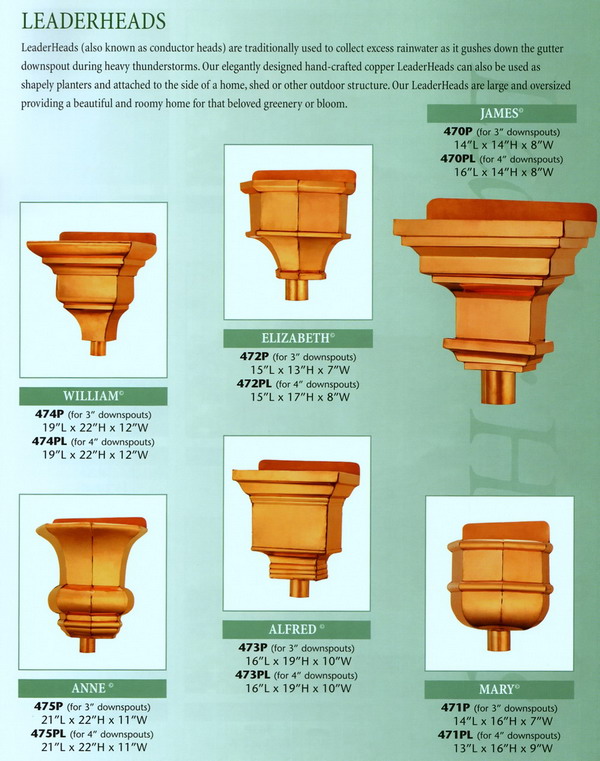

Other Fancy Leader-heads I could make |

|

Here are some more examples of fancy styles that were made in foreign lands by slave labor, but are no longer available. They are examples of shapes I could recreate, so if money is no object these are options to choose from in any size that would range from $500 to $900 each depending on the details. Contact us for specific current costs for the details and sizes you need. |

.

| A few other scuppers I installed, but did not make | |

|

A small 9" wide scupper  These scupper were soldered together the old fashion way. This use to be the best way to seal copper, because they did not have the kind of advanced caulks we have today. The old copper scupper below was made of a paper thin easy to work with copper sheet-metal. It was a little dented up along the top rim, but no evidence of a major impact that caused the solder joints to crack apart. Also wear from rain and debris it had actually worn holes clear through the side walls of this thin copper used to make it. |

A larger 18" wide scupper  |

|

Because of this evidence; we installed the large scupper above with a simple copper funnel insert inside as a liner, to funnel the water smoothly into the outlet in the bottom without wearing the thin side walls of the new scupper the client had sent away for.  |

|

.

| Different Downspout Options |

To see and read more about the different downspout configurations just click on the pictures here. |

|

Ordering Details |

|

Lead Time You can get a better idea of what my current work schedule is by going to Latest News page to find out the most current lead-time listed. If you are in a hurry; to expedite this process, some clients have sent in a $200 reservation deposit even before we were able to work out all the details, so that they would be scheduled next on my list of projects. This takes the pressure off from making a hasty decision. I will refund 50% of that deposit if for any reason you changed your mind and did not contract with me, no questions asked. Click here for our contact and payment info. I strive to check for new e-mail at least a couple times each day 7 days a week, and respond to those e-mail personally within 24 hours, so working out the details should go swiftly. I do have a toll free phone# listed on our Contact web page that rings my cell phone, but I do not quote prices for custom work over the phone. That process may take me several hours to do the calculations if I have all the measurements, diagrams, and clear photos from you to work with. Also, neither of us would then have a written record of what was said, so it is important to have received an e-mail from you with your requested project details.

Time:

Payment: |

|

Prices: |

|

Minimum Order: |

|

Scupper

Sizing: |

|

Why

Copper Sheet Metal? |

|

Sheet Metal

Thickness: I feel that since the cost of labor and freight is clearly the largest part of the cost for any custom work like this, so why not use a better material, which will last and is more impact resistant? I have seen where those scuppers made in a thinner copper will get dented and even wore holes through the sides within a couple decades, so if they now need replaced they might as well have just used steel to make them, since they did not last any longer. I also build a smooth funnel liner inside most of the scuppers I make to take the abuse of decades of running debris mixed in the rain water for this reason. So that is a combination of 40oz copper to their 16oz copper. |

|

Volume

Discounts |

|

References Go to our referral web page for letters we received about our work practices and the quality of our work. |

|

Other Items |

.

.

|

Helpful Roofing Information For some valuable advice with regards to roofing and rain management issues check out our:

(a)

Gutter Installation web pages for answers and solutions that could save you thousands of $ and a great deal of anguish. If you do find this information very helpful, feel free to send us a $ tip for the assistance we so freely have published on the web here for your benefit, like you might tip a waitress. Heck, send us a gift certificate for a candle lit dinner for two. |

.

|

Below is a

photo of our |

|

We were also a 1997 finalist for this same award. See our referral web page to see how we managed to be honored with this special award |

Homepage |

|

|

Company Profile |

|

Roof Caps |

|

Chimney Caps |

|

Scuppers |

|

Gutters |

|

Shipping |

|

Contact Info |