|

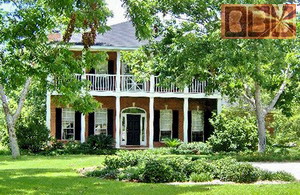

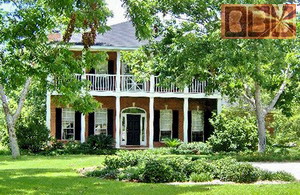

This chimney cap is for

a client named Mike and Teresa Trainor

in Fairhope, Alabama, who lost their chimney cap in the Katrina storm.

We did most of our correspondence with Teresa. She contacted us just

after the first of the new year and we exchanged just over 100 e-mails

in working this out over a couple months until she was able to share

the installation photos with us.

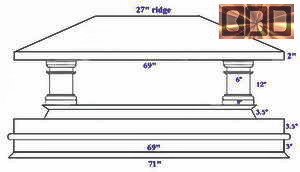

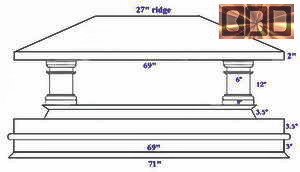

The final design has a 6/12

pitch hipped roof and the base is 71.5" x 44". There is a pan built

inside to shed rain that might blow inside under the roof. The cap was

co-designed by us and the client. It took several diagram revisions

to get the final design locked down. As you will see here;

we recreated this diagram with great accuracy and detail.

We

weighed this to see what was the actual amount of copper used in this

fabrication; and without the wood frame it weighed 182.5lb. Which divided

by 1.25 equals 145.6 square feet of 20oz copper used in this chimney

cap. We multiply this by our base rate of $25 which totaled $3,640 +

$300 for the large wooden frame base. We spent another $65 on the engraved

plaque she had requested be applied to the cap.

Cost: $4,000 delivered

There

was a ceiling on the price of $4k, but we still wound up using a good

deal more copper in this chimney cap than we had estimated. So

the building of the wood crate and the $300 shipping charge was pretty

much free of charge to the customer. We worked on this for over 3 weeks

and they saved about $1,000 on this.

|

|

Here is the e-mail we got

from her just after the installation:

From: "Teresa S. Trainor" <tstrainor@bellsouth.n*t>

Subject: RE: YEA!!! We have installed the chimney cap!!! - 4 Pics

Date: Fri, 3 Mar 2006

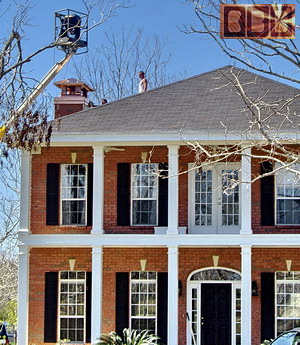

Yes! We got the cap

installed today!!! It looks fantastic – everyone is raving about the

work you did. One of the guys on site doing a custom ceiling in my family

room said it was the finest copper fabrication he had ever seen in his

life, and he is a seasoned craftsman. Attached are the installation

pics. We ended up using a lift truck as a crane. The whole

thing went very smoothly! It was very exciting. I cannot tell you how

happy we are with the end results of all of this. You are

truly to be commended! Thank you for a wonderful piece of architectural

art.

|

|

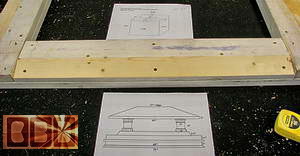

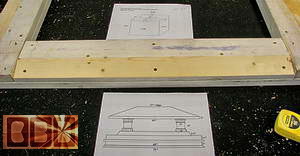

It is designed to

be mounted on this wooden chimney chase that is surrounded by bricks

on 3 sides, so we also needed to make a

custom wood base for the copper base section to gently rest on.

The

base was made with 8 overlapping pre-primed 5/4 x 6 boards with a 2x3

inner support for the center section for under the columns. They are

screwed and glued together with Gorilla Glue. The wood was angle cut

at the top of the wooden frame on our table saw to better match the

angle of the copper base section.

|

|

Here is one half of the copper base being formed.

and set on the now painted wood support frame.

Here is the other half of the copper base attached

to the first half. Then some custom arched copper cross braces installed

in the center to support the pan that will go over it.

|

|

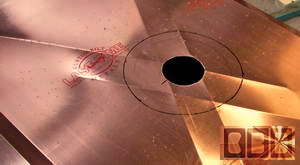

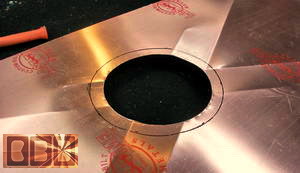

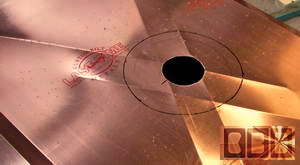

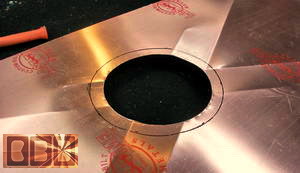

Here is the overlapping

pan gong on and the flue hole being cut into the center 1/2" wider than

the outside diameter of the flue.

Then the 6" tall collar is sealed to the pan flanges. Then the pan

is riveted down to the base and the cross braces. You can see here the

center set of 2x3s used to help support the weight of the pan and roof.

|

|

This

shows the pipe attached to the sides of the base. This will add strength

and also add a decorative touch. We custom cut each side pipe with a

mitered cut on each end. Then riveted it from inside the base.

|

|

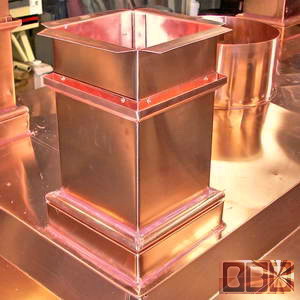

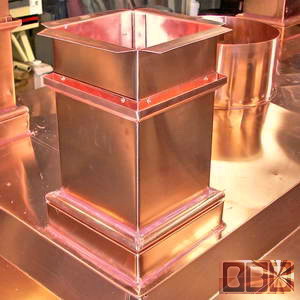

Here is the columns

being built to support the roof. This was a special challenge to build

these strong enough to withstand hurricane weather, so we used a set

of 5 stainless steel bolts for each column to hold these columns in

place, along with several rivets.

Here is the decorative

trim being added to each of the columns.

This is a tedious process

that takes a lot of time, but not a lot of copper that we can charge

for.

It took several days

just for this portion of the project.

|

|

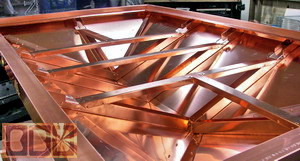

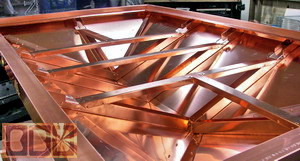

Here is the support

cross brace made for the roof framework to be mounted on.

We have to be mindful

of how it will be seen from underneath, since that is how this will

be seen most from the ground.

It needs to have a solid regal look

to it.

|

|

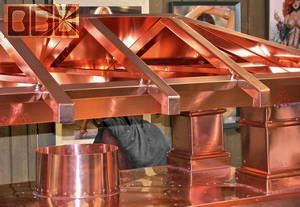

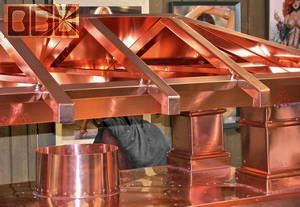

Here is the roof framework

being built over the sub-frame.

Then the roof skin is custom fit and attached to

this framework.

As you can see; we

have not yet secured the sub-frame on the columns

Here you can see the

roof separate from the sub frame, and the wood frame has it's final

black paint coat.

|

|

These are outdoor daylight

photos for a better look at the details.

|

|

Here is the stainless

steel screening over the flue collar we made with a copper top and bottom

frame. The top screen frame dips down in the center to help divert the

smoke to the sides. The bottom frame will help keep the SS screen edges

from wearing holes in the pan and holds it in place. I wanted to make

a square screen area to match with the square columns that also match

the front of the house.

|

|

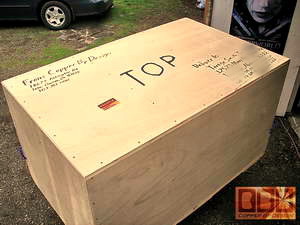

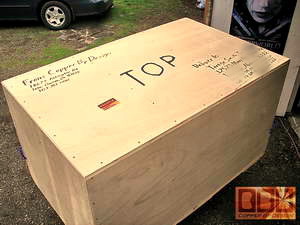

Here is the custom

wood crate with a hardwood plywood skin over this framework. The whole

top and sides lift off the crate base for removal when it arrives to

it's destination. It is screwed to the base.

|

|

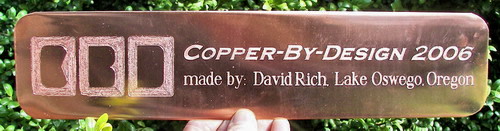

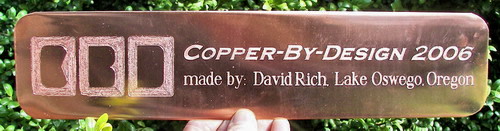

Here is the commemorative

plaque that Teresa Trainor had requested early in the quote process.

We had this sheet of copper engraved at the cost of $80 to this architectural

art sculpture we had made. We riveted it on the back side of the chimney

cap base, so it can be seen from the ground, but is not too obvious.

So far she is the only client to even request this archival detail,

so we have not seen the need to buy the tooling for making these plaques

for all our projects. It is something we may look into some day, but

for now it would be a $100 option added to the cost.

After over 3 full weeks

of construction it is finally ready for delivery!

|

|

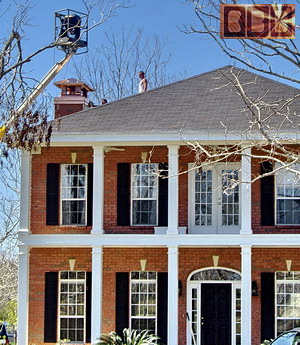

In these photos they

had already secures the wood frame over the chimney top with the SS

lag screws we provided. The rest speak for themselves. Thanks to Teresa

for being so kind to share these photos with us.

|