|

It seems that I may be the only shop

in Oregon willing to make these sort of custom flashing kits for

chimneys, and perhaps the only shop throughout the USA. Other shops will not understand these sort of requirements

needed for such a kit, or do not want to

bother dealing with Homeowners on such small $ orders like this.

Wehre I have personally reflashed dozens of chimneys, so I have a

much better undertanding of what this requires. I also make these

kits using a thicker copper than other shops.

This is

where I come in

Why is this such a

problem that I would need your service?

This is a huge problem

within all States,

because chimney flashing has clearly been the #1 most

neglected area of a roof done by even the most professional Roofers when reroofing

your house. It is very rare they will

even bother to replace the counter-flashing at all, let alone use a

rust free flashing in aluminum, stainless steel, or copper. Any other metal than steel,

so that is

sure to not rust away over time.

Believe

it or not using a

cheaper steel flashing in stead of a thicker aluminum around your chimney saves them

less than the

cost of a burger, but they don't seem to care. Painted steel is

use over 95% of the time, even though they know it will not even last as long as just

a low life 25 year shingle.

From what I've seen Most Roofers will not even

bother to replace that old flashing at all. No matter how rusty it is.

As you can imagine steel flashing should never be reused even if it

had not yet started to rust. It should always be replaced when

reroofing a house, unless it is a better solid copper flashing, since

steel could not possibly hold up for the next

several decades like the new roofing should. It is just plain simple

logic, but seems to escape so many Roofers.

I just came back from the

Nation MetalCon in Denver 2014 and saw how 90% of what they were

pushing was painted steel for exterior applications. It sickened me

to see such horrible standards being shamelessly represented there.

I kept saying to those reps at each booth: 'You know iron is a 4

letter word, right?'. I would often go as far as to exclaim how I

believe 'steel' needs to be made illegal for any roofing

applications! They looked at me as if I had just insulted their

Wife. Sadly I doubt I had made much of an impact on how they will

continue to do business. I go into this in more detail on my web

page about Roofing.

If your flashing is not

yet showing signs of rust you can do a simple magnet test to

tell if you have steel flashing, since only steel with iron will attract a magnet, out of all the

many other different types of metal: aluminum, zinc, magnesium, brass,

copper, bronze, good stainless steel, titanium, silver, gold,

platinum, and several others not mentioned here. These metals may

oxidize, but they will not rust within a decade of exposure; causing unsightly stains and

developed holes soon after that. Steel is a cheap sturdy metal

that handles heat well, but mostly used for it's planned

obsolescence than any other reason. The fact it does not last long just helps

their profit margin for repeat business, yet how much will you and

your house suffer after the leaks start showing from inside before you have

a chance to find a

reliable Contractor, then wait for them to fit you into their

schedule.

Ironically before those

same Roofers had mess with your original

chimney flashing there in front of them is a good example of how

flashing is suppose to look, yet most Roofers

will be quick to say it cannot be done that way ever again w/o rebuilding the chimney, but I have personally re-flashed hundreds of

chimneys in this manner, proving that is simply not true. They're

just too lazy to do it the right way. In many cases they will just

smear some tar around the chimney to get them past the 1 year

minimum warranty

they're obligated to provide,

but that certainly will not last more than half a decade at best. Here is a

common example of this sort of shoddy workmanship before I

replaced the flashing seen on the right.

With my vast experience

and unusually high mechanical comprehension I have a pretty good understanding

of what it takes to do the job right w/o the need for messy caulk. These flashing kits I make

have

become a very popular item with clients across the Nation here in

the States, since

no one else seems to be offering this sort of personalized service

to Homeowners, or Contractors. I may not get it perfectly right each

time, but I do my best.

I resist pushing more

parts than what people may need, and wind up having some whole

pieces left over when they're done. So, if you do want me to add

extra flashing pieces in order to make sure you will have enough,

and perhaps be able to replace a piece that may get damaged in the

process let me know.

What do you base

the cost on with these irregular pieces?

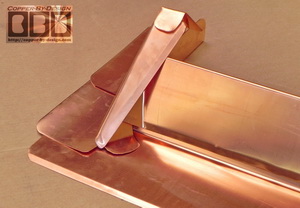

The cost of these kits are based on the final weight to determine

exactly how much copper went into it priced at that $25 rate per

pound, so

you will not be paying for any cut-off waste, let alone an inflated quote

you're likely to get from other sheet metal shops. That's one

heck of an honest deal that you're not likely to find elsewhere.

It's also

a detail you can double check when your kit arrives to verify just

how honest I was.

For me it's a great way to use up

some of my

smaller cut-off scraps of the 20oz, 24oz, & 32oz copper sheet metal I have left

over from larger custom copper projects I build, like

chimney caps,

fire-pit covers, and

turret roof caps, so I am able to sell these kits for lower cost

that my other custom work. That's a good 30% less than most of my

other custom copper work, at my base price of $35 per pound.

Although, the more complex sealed

crickets I make run the whole $40 pound

for the copper and $15 sq' for the wood support under them. Plus the

crate, packaging, and freight also goes up substantially given their larger size than just

a basic flashing kit that can usually stack inside a compact box. This can add over twice the cost to a kit, but it

is well worth the functional advantages.

Why not just

aluminum to save money?

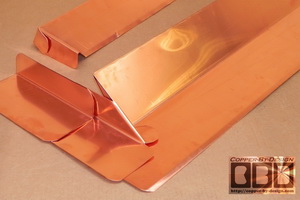

I can make

these kits in sturdy painted aluminum if you want, such as these:

Alum.htm

But

the disadvantages are not really worth the minimal savings. I appreciate

your concern about keeping costs down, but aluminum would be more fragile,

the paint and

mildew issues decades later making them not reusable the next time

your house is reroofed. Also, copper may cost me

5X more than aluminum, but when 80% of your final cost is the wood

support under a saddle, design, fabrication labor, a custom

crate, freight, and then labor to install this after it

arrives, so it would be unwise to use a cheaper metal. I trust you

can agree it is best to do this with copper and have it

done with the piece of mind you're not going to have with other

cheaper metals.

As much as 30 years

ago I've seen Masons charge upwards of $750 to re-flash a single

flue chimney with just cheap painted steel. With inflation imagine

how that would cost you 3X today. They

had saved less than $75 back then by using steel in stead of the

standard 16oz copper at

just $3.25#, where it is over $8# these days (2022). If done with

copper you should not need to redo it again the next time roofing is

required. Or perhaps even the next several times.

Aluminum would easily last several decades, but the paint would

flake off over time and begin to look terrible, so it is not

as reusable as copper or help against mildew stains. It would also crack more

easily when your next Roofer has to bend it up to fit the new step-flashing

in under it as they re-roof your house, since copper is much more malleable. Another

clear advantage

is how it will retard the growth of mildew and moss on the roofing

around it. Copper will patina to a satin brown color within a few

months of exposure as well, making it the best possible choice.

Isn't

this going to be too complicated for me to do?

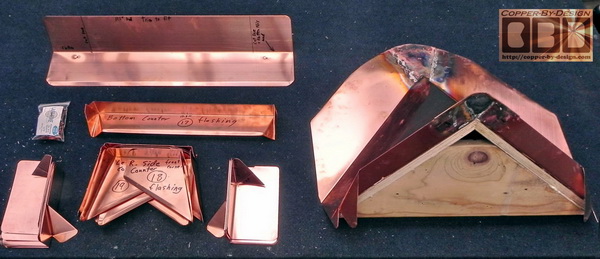

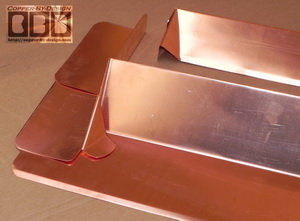

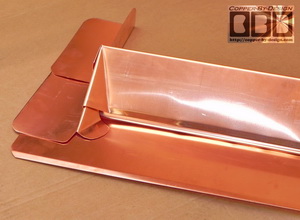

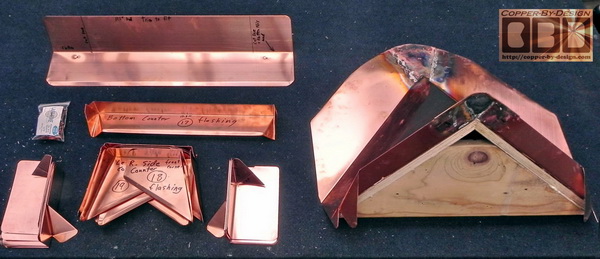

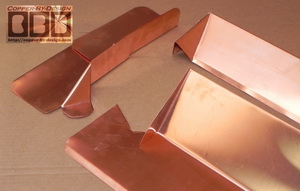

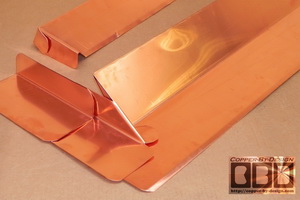

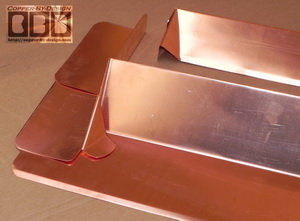

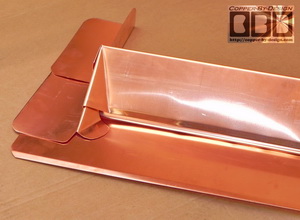

Believing you can do this may be your most

difficult hurdle. Below are

several photos of these chimney flashing kits installed by Homeowners

just like you. Each piece in

these kits are labeled and numbered as to where they go and in what

order they are to be installed. We also round off the

sharp corners, so there's less chance of getting cut while handling

them. We also include the copper roofing nails you'll need, so

all you should have to pick up locally is the mortar and some hand tools, as described in the

instructions 'PDF'

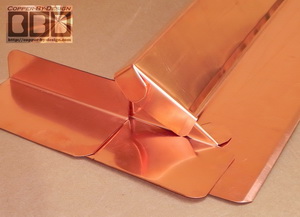

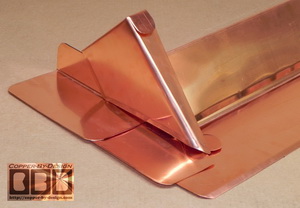

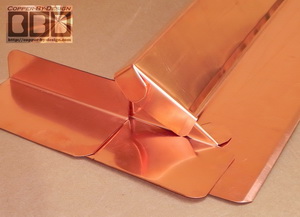

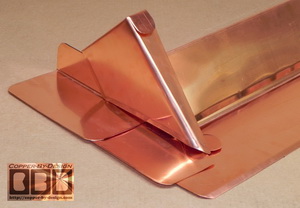

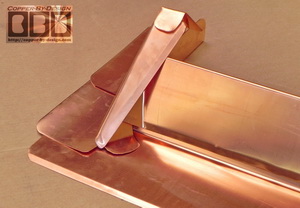

file I provided. These 8 photos show how these pieces are fitted

together around the lower corner to seal w/o the need for caulk, while

allowing for movement from expansion and contraction of the wood

structure against the clay flue as the

temperature changes.

Side diagonal step-flashing is set

against the horizontal base piece to overlap and fold over.

The horizontal counter-flashing piece

overlaps over both of them and folds around the corner.

Then the side counter-flashing piece

overlaps those 3 pieces up in the next course of brick above that folded

around the corner to help keep this corner sealed even in a wind

storm.

Here is a link

to an educational video showing an amazing looking copper flashing job that

is far more complicated than the kits I supply:

http://vimeo.com/30283585

Although, you would do well to consider how it would be far too

expensive to be practical, when it would cost several thousand,

which is almost as much as a whole reroofing project of your house.

If that's not enough of a deterrent the

worst part is how this will be near impossible to reroof around it

without destroying all that beautiful work he did, since there's no

way to remove the step-flashing around this chimney. I also have a

problem with how low he made the side counter-flashing that touches

the shingles, which will not allow for any expansion of the house;

which will differ from the masonry. Soon after the counter flashing

will be crushed from below and destroyed. That is why there needs to

be this 2 part flashing system to allow for this movement and

maintain a good seal.

Also, the reverse hem of the counter-flashing that

penetrates the chimney may seem like a good idea, but that means you

have to install it before it gets mortared in, which means the

bottom is not attached and the 1/2 that does touch the upper bricks

will probably crack apart and fall out of that grove within a year

or two, just like with most all tuck pointing work that fails within

a few years.

Can CBD make us a reliable custom copper

chimney flashing kit?

My base rate for our custom work is $35#

for this copper. Although, I've made up hundreds of these custom

chimney flashing kits for as little as $25# for 20oz & 24oz copper flashing, as indicated by the final weight, plus

freight if you are not local to us. A single flue chimney flashing

kit runs about $400 w/o freight.

What about for ice & other severe weather

condition areas?

For a bit extra I can

make these flashing kits with a taller 3" to 4" vertical flange if you want.

You may feel it is needed there in your area, due to the more

extreme weather conditions you may have; like ice dams forming to

back up water under the shingles. Please, mention this when

requesting a quote through

e-mail, or I may not offer it. I try to refrain from up-selling my

clients.

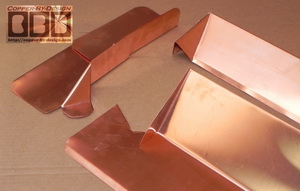

In my effort to seek a better product for my

clients I have designed a special type of

step-flashing with a pair of 45 degree bends, in stead of just a

simple 90

degree bend, which is an improvement over the standard right angle

bend configuration normally used. This has several advantages, yet

may be difficult to fit into some situations or types of roofing. Here are a few photos of this

alternative flashing being

installed by one of our clients:

Sealing around the corners of a chimney has always

presented a problem to make sure it's water tight without the use of

a caulk, which could fail sooner than the life span of the roof. It

needs to maintain a seal even in the harshest wind storms. I have

found this alternative shape helps in several other ways as well:

(a) navigates the rain water out away

from the corners of the chimney a bit better.

(b) slows the water down and reduces

upward splattering under the counter flashing.

(c) helps to be able to

trim off the commonly compromised and damaged shingles nearest the

chimney when replacing the flashing without a full re-roofing

project, thus reducing the shingles needing replaced around the chimney.

(d) helps reduce scraping needed

where the chimney meets the roof: old caulk or sloppy mortar work.

(e) makes it easier to cut the new

grooves without needing to grind so close the the roof.

(f) application of an underlayment resting

up against the chimney for added protection is also made possible;

without such risk of cracking that membrane needed with conventional

flashing.

To see more photos of this installation

follow this link:

http://copper-by-design.com/rf/Druschel.htm

Let me know if you need any special

configuration and we'll customize your kit.

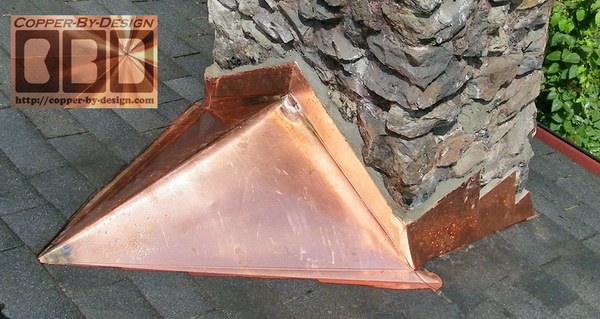

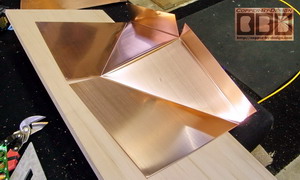

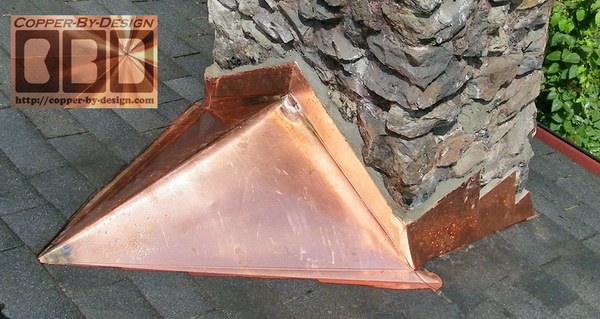

What about a cricket or saddle?

They are very helpful to divert the

rain water and debris off to the sides. I build these custom saddles to match your roof angle with

wood support attached underneath

for a sturdy simple one piece installation, in stead

of just the normal horizontal tray that traps lots of debris. They

run about $45 sq' + freight. Wide saddles over 36" would need to go

truck freight, which can be several hundred depending on the size

and weight.

This can be one of the most important details

of a new flashing kit. The upper side should have a saddle, but it's not required with a flashing kit order. It is

just highly

recommended in order to help divert the rain water and debris off to the sides of

the chimney. As opposed to just a simple straight horizontal tray, like you

probably have now. Especially if your chimney is wider across the upper

edge.

Those common horizontal

trays catch a lot of debris, so they're if not cleaned out frequently that

debris compacts and decomposes, holding moisture against the metal

between rain storms. I design these saddles to drain the water 2" out past the

side flashing. Also made with a wider outlet than any others I've seen,

so debris is less likely to damn up. If you are interested in one of

these custom saddles please be sure to mention this in your e-mail, or I

may not offer it. I try to refrain from up-selling my clients.

With your measurements we

make the careful calculations and form this to fit just right and

sealed water tight. If you could get some larger sheets of paper to

hold up against the sides of your chimney to trace the roof angle

and the mortar groves between the bricks that would assure a better

more precise kit preformed for you in advance, so little

customization is needed by you. Then fold those up and mail them to

me. I do not require this. I've made most of our kits from just a

few measurements and digital photos to reference. That is just a

sure way to make sure this would fit as well as possible.

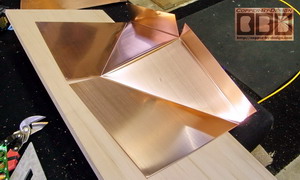

These photos show duel sided discharge

chimney saddle to replace the straight horizontal tray may have.

I make it as seamless as possible and sealed with a cover piece over

the splits soldered in place. You could make the plywood

support for under the saddle, but there is a strong likelihood my

copper saddle will not fit perfectly over it, so it's highly

recommended to have us fit it in and bond it to the wood, so it has

an air tight seal and condensation will not form under the copper

to make it all nasty. Otherwise you'll need to use an expensive

high temp Water & Ice Shield underlayment, like I use on other

projects:

http://copper-by-design.com/cw/Edwards.html

A

little personal history:

I originally built a sheet metal shop in my basement to

custom fabricate my own aluminum drip edge flashing for the gutters

I install. A couple years later I paid the 5X cost for

roofers liability insurance for several years and replaced many

roofs, but with no

employees I could not do the volume of work it took to afford that

expensive insurance. Over the

last 2 decades my little sheet metal shop has grown

and evolve to building many different custom aluminum, stainless

steel, and now mostly copper rain management

products that can be seen on this web site.

I use to be very intimidated by the

high cost

of copper even before it had doubled in cost back in 2006, so I used a

clay red pre-painted aluminum flashing for chimneys, knowing it is a lot better than

just the

cheap steel

that is normally used. I stopped using aluminum all together for

chimney flashing around a decade ago. The

cost difference between using a cheaper metal was not worth it's

disadvantages.

Especially considering the

amount of labor this type of project requires.

There needs to be this 2 part flashing: the

step-flashing is integrated with the roofing and sets up flush against

the side of the chimney. Then the counter-flashing is mortared in between

the bricks in horizontal lines only to overlap the step-flashing.

This 2 part system allows for the movement that is caused with the expansion

and contraction of these 2 very different types of structures: wood

and brick, while

maintaining this seal. Of course the bricks will expand with temperature

changes differently than the wood structure of the house. Even 1/4"

movement would be enough to rip open any other system used to seal the

chimney to the roofing. This is not a new method by any stretch. It

is a time tested technique used for centuries, and I have yet to see

a better technique for this purpose. Elastic rubber membranes will

remain flexible for only so long, and will not outlast even steel

flashing.

What

info do you need from me to make a good custom kit?

(a) Good clear photos. Fortunately most people now

days have a digital camera and know how to send picture through

e-mail. I've successfully worked with thousands of client this way

over the last decade. Most of my clients have been back East on the other side of the country. It's important for me to

see what your situation is up there, so I'll need some fairly

close-up photos showing the sides of the chimney where it meets with

the roof, as well as whole shots.

(b)

The roof angle is important, so I can cut the counter-flashing at just

the right angle, minimizing the copper you'll have to pay for and

less cutting copper pieces there up on the roof to fit. The roof angle is based on how

far the roof drops for every 12" straight out. It's best to

have a level to make sure the 12" is horizontal, then just how far

straight down from the end. You can use a board laid flat on the

roofing to get a better idea of the real slope of the roof, as

shingles can be lumpy. (b)

The roof angle is important, so I can cut the counter-flashing at just

the right angle, minimizing the copper you'll have to pay for and

less cutting copper pieces there up on the roof to fit. The roof angle is based on how

far the roof drops for every 12" straight out. It's best to

have a level to make sure the 12" is horizontal, then just how far

straight down from the end. You can use a board laid flat on the

roofing to get a better idea of the real slope of the roof, as

shingles can be lumpy.

(c) The measurements of the

chimney at the point where it meets with the roof of course. These

measurements should be as accurate as possible, so I can do as much

cutting and bending for you as possible, so you will not have to do much

customizing yourself up there up on your roof.

(c) As I said

above it would greatly help if you could get some larger sheets of

paper to hold up against the sides of your chimney to trace the roof

angle and the mortar groves between the bricks. That would assure a

better more precise kit preformed for you in advance, so little

customization is needed by you. Then fold those up and mail them to

me. I do not require this. I've made most of our kits from just a

few measurements and digital photos to reference. That is just a

sure way to make sure this would fit as well as possible.

|