|

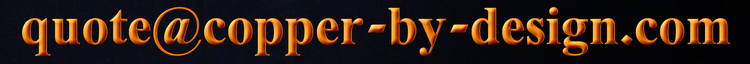

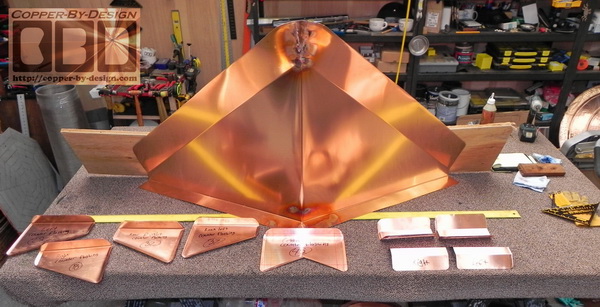

Here are some

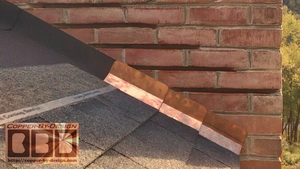

photos of a common chimney flashing kit custom made for our clients

Ralph and Media Druschel in Zelienople, Pennsylvania for the new

house they are building. This custom saddle has been designed to

have the same sideways slope as the roof and has been reinforced with

1/2" plywood to have the same strength under the copper as their

roof. This makes for a simple to install single piece design. I

could make a copper cover to go over an existing frame, but there's

a much higher chance it will not fit just right. This wood has been

glued up inside this copper cover.

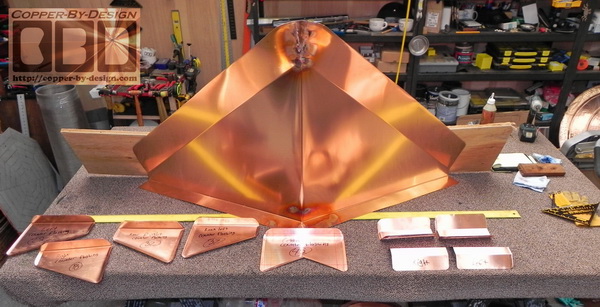

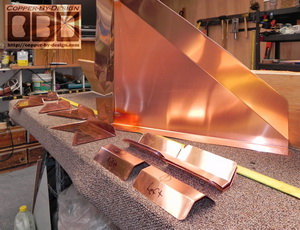

The flashing kit

has been numbered and labeled to help the installer know how it is to

go in place and in what order. I wasn't satisfied

with the standard flashing configuration, so I recently designed a special type of

step-flashing with a pair of 45 degree bends instead of just a

simple 90

degree bend, which is an improvement over the standard right angle

bend configuration normally used. This has several advantages, yet

may be difficult to fit into some situations.

Sealing around the corners of a chimney has always

presented a problem to make sure it's water tight without the use of

a caulk, which could fail sooner than the lifespan of the roof. It

needs to maintain a seal even in the harshest wind storms. I have

found this alternative shape helps in several other ways as well:

(a) navigates the rain water out away

from the corners of the chimney a bit better.

(b) slows the water down and reduces

upward splattering under the counter flashing.

(c) helps trim off the commonly

compromised and damaged shingles nearest the chimney when replacing

the flashing without a full re-roofing project, thus reducing the shingles needing replaced around the chimney.

(d) helps reduce scraping needed

where the chimney meets the roof: old caulk or sloppy mortar work.

(e) makes it easier to cut the new

grooves without needing to grind so close the the roof.

(f) application of an underlayment resting

up against the chimney for added protection is also made possible;

without such risk of cracking that membrane needed with conventional

flashing.

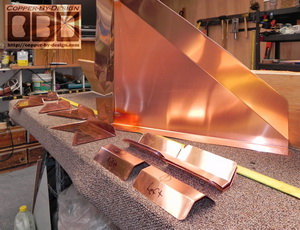

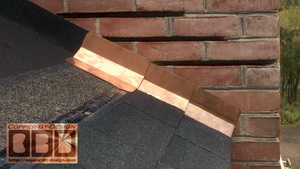

Here is a great set

of photos sent to me, taken with my client's cell phone while I

helped walk him through the process of installing this copper

flashing kit I made him. This shows him test fitting a few pieces first.

He loosely laid out shingles and

flashing in place to capture these images, so I could see if he was

on the right track.

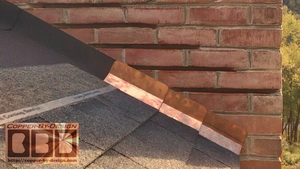

The saddle seen here had some minor

damage during shipping, but he was able to bend it back in shape. It

would have been too costly and time consuming to send it back to

have me fix it, or remake it. This is one of the advantages in using

a malleable metal like copper. He marked a line on this piece of

flashing as an indicator of how the counter-flashing will need to be

positioned over this flashing to allow for some movement as

temperatures change.

Here he has now gotten

the confidence to start nailing down shingles and flashing. It is

important to punch the nail hole through the copper flashing with an

ice pick or similar tool, or you could wind up bending a lot of

these copper roofing nails I include with each flashing kit.

Most of these

copper roofing nails will be driven through 2 layers of shingles and

copper flashing. You could run the nail half way up each piece of

flashing, but then you would only have 1 nail holding each piece of

flashing in place. Set lower makes it go thorough the lower flashing

as well for a substantially more secure hold and less chance of any

movement.

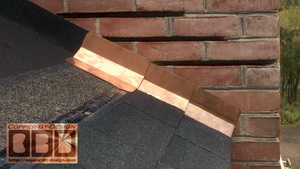

This layered

installation will provide a good water tight seal without the need

for any caulk. The tab of the flashing that lays flat on the roof

deck should be completely covered by the next row of shingles as

seen here. Remember you can click on each photo to get a better

look.

When you reach the

top corner this right angle bend has to be custom formed on site to

seal against the top flashing pan. Be it a full saddle with the same

sideways pitch as the roof, or just a simple horizontal tray to

divert the rain water off to the sides of the chimney.

This top tray or

saddle needs to be made several inches wider than the chimney to

drain the water out past the sides a bit. It is also important this

has a wide outlet mouth on both ends, so there is less issue with

debris getting trapped in this area.

The extra ends of

this upper tray then need to be folded over the step flashing to

help seal it to the side flashing. The outlet drip edge flange is

also bent down to meet the shingles.

Now he's ready to

mortar in the counter-flashing pieces over the step flashing set

installed. It is imperative to have this 2 part flashing system, so

as temperatures change and the wood structure expands and contracts

differently than the clay structure of this chimney they will be

able to allow for this movement while maintaining a water tight seal.

With even a 1/4" movement any caulk used would be torn apart and

made irrelevant. The counter-flashing needs to be installed with

this in mind, so it is not mounted too low to the step-flashing

pieces and saddle.

To see more photos of this installation

follow this link:

http://copper-by-design.com/rf/Druschel.htm

Let me know if you need any special

configuration and we'll customize your kit.

|