|

This set of solid 20oz copper

turret roof caps were custom made for a client named Amanda Grassham

of

Grassham Lumber at 202 Sycamore St.,

Van Buren, Missouri. Phone # (573)

323-8458. They had a client with a house that

needed these 2 turret roof caps, so she did the research for them and

found our web site. I do not often see lumber yards go to this

kind of trouble for their clients to research the best options and negotiate

for such unusual one-time requests. If you happen to live in the Van

Buren, Missouri area she's your rep:

(573) 323-8458

fax#

573-323-8542

e-mail: grasshamlumber@semo.net

She was able to get

us all the necessary info in her first letter, so she qualified for

our 'I Did My Homework' discount. They also got $100 off for getting

a set of two identical roof caps together. They originally requested

the set to have these alternating tail designs, but after I made the

template and sent them a photo, the client decided it would look a little

too odd, so they scrapped the points tail design.

It is for their 14/12 pitch

circular turret roofs, so we made these at a 16/12 pitch with 16 uniform

sides. These roof caps are 33" wide plus the Jabush tails designs.

They are made with a 3/4"

type L copper pipe in them for a finial support with solid brass mast

rods and a set of Merlin finials. It was my job to make it strong and

seal the top of the roof. It is important to make sure the pipe is straight

in case they some day want to change one of the finials out for a weathervane.

If the pipe is not perfectly level the weathervane may not rotate freely.

The base of this pipe is

capped off with a larger cap, so the rivets will not interfere with

the brass mast. It is soldered and then drilled for long copper rivets

to hold it securely in place, so it is independent of the wood roof

structure.

The union here is then caulked

over to make sure it is sealed. I then cover that caulk with a fabric

gaffer's tape after that. The steeple cone is then riveted onto the

base cap through the hidden flange under the edge of the steeple cone

from inside the cap base

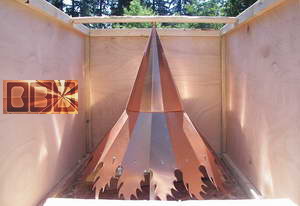

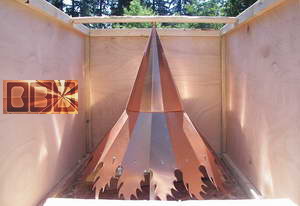

When the roof caps are finished

I need to build a special custom wood shipping crate to safely transport

these back East.

This is tricky since I cannot

have them rest on their fragile tails. I have to make this set of padded

stools for them to rest on and secure the tip of the cap so it will

not move inside the crate. I have to anticipate the worst-case scenario

during transit. The other stool is attached to the roof of the crate.

One of the copper roof caps

is set upside down in the crate to help minimize the size of the shipping

crate and it's weight. That does mean all the weight of that cap is

going to rest on the tip bouncing up and down in the truck. I am that

confident about how strong I have built these.

The crate frame is covered

with a hardwood plywood. This will hold the crate sturdy from any movement

or shifting in transit.

Cost: $1,574 for both php

|