|

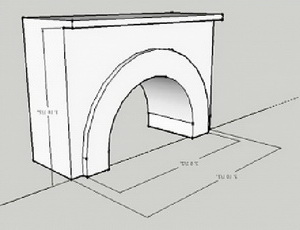

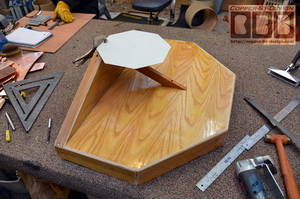

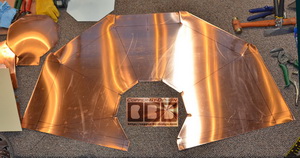

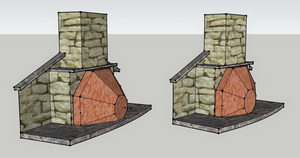

After finding our web site Michael Klinglesmith here

in Portland, Oregon wanted us to build him this copper cover for

the pizza oven he built in his back yard. I was able to form

this in just 2 pieces. The main angles cover that wraps around

the wood frame is all one piece, and the 11" octagon in front

was soldered in place and wraps underneath.

Michael was going to have me make just a basic

33.5" wide 20" tall rectangular cover to help keep it clean when

not in use.

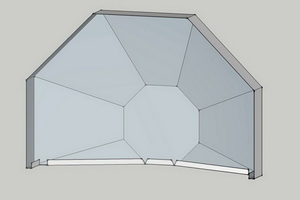

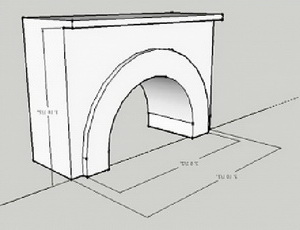

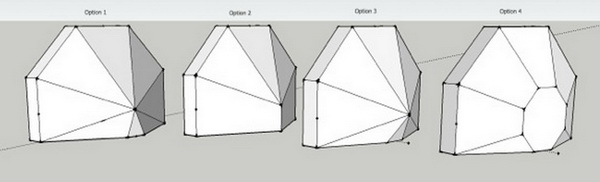

I suggested he should have me make this

cover more stylized in this way to accent the arched opening w/o

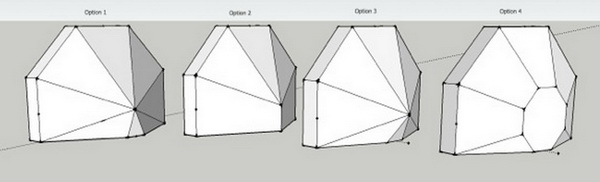

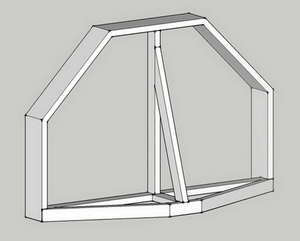

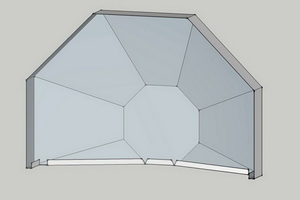

costing more. He got inspired to work up all these 3D diagram shapes to help

visualize this before having me form this in copper. I was very

impressed with his ability to imagine the shapes I had described

to him with such accuracy. As you can see he chose diagram #4.

He says he is willing to do this sort of 3D diagram work for my

other clients if they want. For a fee of course. If you would

like this sort of rendering service his contact Ph# is (503) 806-7519,

or e-mail him at:

mklingles@comcast.net.

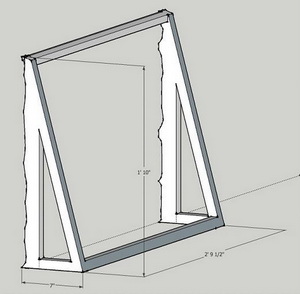

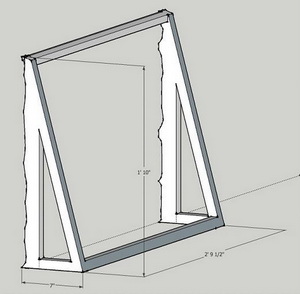

From this 3D rendering

he was able to build this wood frame for me to mount the copper

cover on. He also trimmed the vertical face to fit precisely

over the irregular stone work for a nice tight fit.

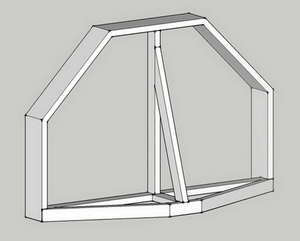

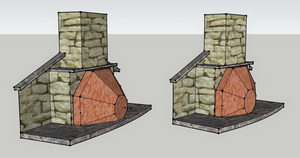

As you can see he did not miss a single

detail in his rendering. He was even able to add this color and

texture to help see just how this would look.

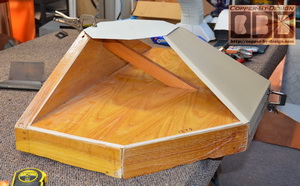

It was very cool to work with such a savvy

client. I made this cover w/2 separate pieces of 32oz

copper and added a pair of brass handles on the sides of this

wood frame he had made.

Final weight 24#. Cost: $460 delivered to his house. I offered

to dive it over, so I could get these great shots of this cover

in place.

|