|

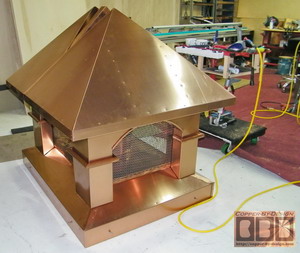

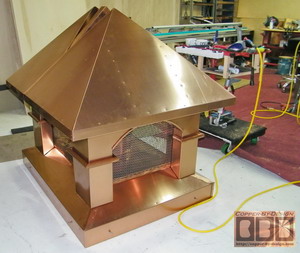

This set of 2 copper chimney caps were for Gordon Swanson

in Waco, Texas installed over their wood

chimney boxes covered with cultured stone work. These are nearly

the same size, but one has an 8/12 pitch hipped roof, where the

other one has a steeper 12/12 pitch. They wanted these built in

my Tuscany arch style that seems so popular. The base sizes: 38.5" X 49" and 38" X 51" ISD.

He first contacted me

3/14/09

and waited for a few months before working out the details of project through e-mails

and put down the 1/3 deposit for this work.

I designed the roof line to resemble their

house with hipped structure, so this will look

more like what the architect might have designed for this house.

The client approved this design and are very pleased with the

results. We

discussed aesthetic options like adding 2" wider

roof that the base/skirt all around.

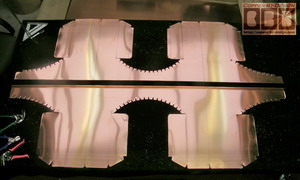

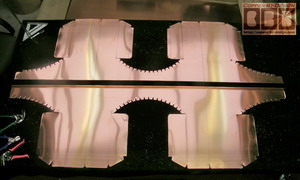

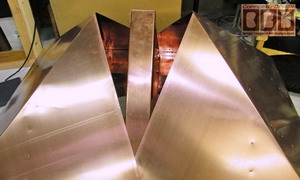

Here's the hardwood boards for the

base/skirt being cut with 45 degree corners and 30 degree edges

on the top and bottom for a drip edge.

|

|

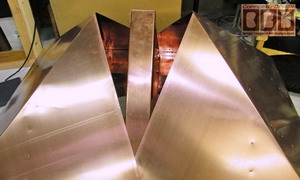

Here's the 4 pieces of Ipe hardwood support frame I need to build

inside these copper base pieces that helps anchor this down in high

wind storms. Each board has been

cut on 4 sides at an angle. They are positioned down low where it

should not suffer heat from the chimney.

The hardwood is glued inside the copper with the expanding Gorilla

glue. It is also held in place with long rivets and I varnished the

inside of the hardwood to keep it dry.

Above left you can see the base/skirt formed. To the right shows the

pan that seals the middle and supports the 15" flue pipe and

there is a channel along the edges that the stainless steel

screen sits into. Below left shows the cross braces that help

support the pan to make sure it will never sag and allow

puddling water inside.

Below is the base/skirt from underneath. I have the clear plastic film removed

where the seams will overlap and where columns will go over this

structure.

This shows part of the arched columns being

laid out on the sheet of copper. There is a good deal of math

and geometry involved here, so it's all in the right proportion

and the bottom of the columns can sit right on the angled base.

Below right shows the 4 inside

liner of the arches formed for this 1 chimney cap.

It took us a few days just to build this set of columns and

arches. Then there was the decorative piping to attach to each

column. Each corner column required a pipe that was about 30"

long. It took the most all of two 10' pipes for these chimney

caps.

|

|

I've cut and bent the 16 gauge stainless steel

screen to set into a channel along the inside rim of the bases.

These screens are what I get my hands lacerated on more than any

other aspect of my work, so it's important to cover all the

edges of this SS screen, so these are safe for anyone else once

these are complete. I happen to get one of the deepest gashes

while working with these screens after I had cut them and was

just turning to leave and caught the edge of a jagged cut. The SS screen is secured to the base through

the 3 layers of copper with dozens of longer rivets.

Then there is the roof support braces to make

and attach with SS screws and copper rivets. I believe this is a

very important detail for large chimney caps like these, which is not done by other sheet

metal shop. At least from what I've seen. I try to make these so

they'll hold up to any sort of harsh weather they may encounter

over the next century.

|

|

The column set of the second chimney

cap is attached to it's base

with 28 SS screws and around 100 rivets. Then several hundred

rivets needed inside to fasten the screen to the back of the columns and

arches. These add a great deal of strength and stability to this

structure once attached. The sides of these arches no longer

will flex more than a 1/8" now.

|

|

Then the eaves are made and attached, which

adds a lot more strength to this arched column set. Then there

is a couple days setting up the roof bracing again. They also

help keep the eaves from sagging under the weight of the roof

skin and what ever may rest on it.

|

|

Then these were ready for the copper roof

skins to go over these braces and attach under the eaves. I

made them as seamless as possible, so they needed these diamond

shaped covers folded over the top.

|

|

I kept track of the weights of each

part for the final cost; the taller one was 205# and

the shorter one was 198.5#

when complete, so the final calculations of what the cost are

for these after subtracting the weight of the wood and

SS screen gives me the weight of the copper. I had given them a discount for this

being such a large order. Weights and cost breakdown of these

pieces are as follows.

Taller Chimney Cap:

-

$150 - for the wood saddle

-

+

$185.04 - 5/4 x 6 hardwood frame inside the base/skirt - 15.42 ln',

34.4#

-

+ $316.40 - SS screen - 15.82 sq', 11.1#

-

+ $3,190 - copper sheet metal -

127.6 sq', 159.5#

-

+ $400 for the crate

-

+ $350 - shipping cost

-

= $4,566.44 total

Shorter Chimney Cap:

-

$150 - for the wood saddle

-

+

$188.04

- wood frame inside the base/skirt - 15.67 ln',

34.4#

-

+ $323.80 - SS screen - 16.19 sq', 11.3#

-

+ $3,056 - copper sheet metal - 122.4 sq', 152.8#

-

+ $400 for the crate

-

+ $325 - shipping cost

-

= $4,267.84 total

$9,034.28 grand total - $2,500

in volume discounts and another $285.72 less than the original

quoted price.

|