|

This set of 2 copper chimney caps for Ed and Gloria Peabody

in Westport, New York installed over their brick

chimneys of their modest home. They first contacted me 12/11/09 and we swiftly worked

out the details of this project through e-mails, and within a

couple weeks they had sent in a 1/3 deposit to schedule this in.

|

|

The larger chimney is 51" long and the smaller on is 39.25.

They both had the same width of 31.25". They originally wanted these built in

just a simplistic low profile style like I had done for a former

clients LEA Construction in order to save cost. Although, just

before I had a chance to begin work on these; they mentioned

concern about restrictions of exhaust flow and wanted to discuss

design alternatives. Keeping in mind how they wanted to keep

costs more reasonable I suggested a simplified version of my Tuscany arch style

that has been so popular. Much like I had done for Mr. Reeves

back in late 07.

|

|

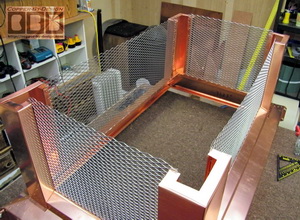

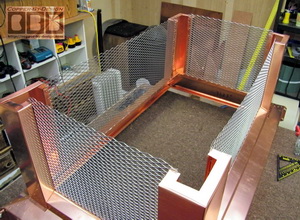

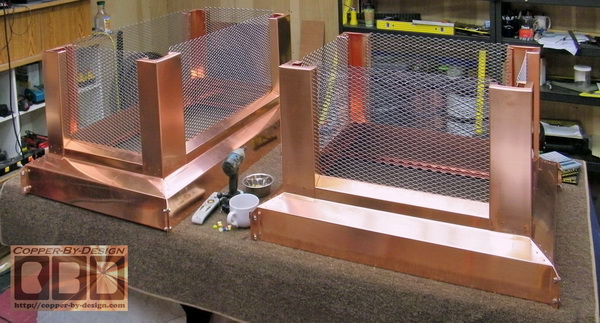

Here's the 8 pieces of the base support frame I need to build

in copper for this pair of chimney caps. This part is what hooks

underneath to anchor them down in high wind storms on the concrete

slab over their chimneys. I had to

make these so the corners can open up to let the metal flex out over

that slab and cups under it for attachment. The corners then will be

fastened together with the pair of stainless steel bolts with

washers and lock nuts on each corner.

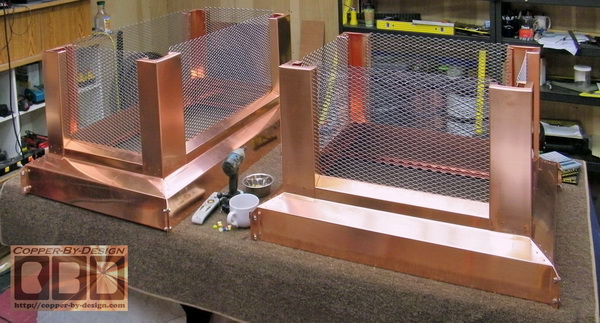

This shows part of the columns

without the arches between them. Each column is attached to the base

with 12 to 13 rivets, but that's not what holds them in place

the most.

These columns hold the sides

of the stainless steel spark arrest screen in place with a

channel formed to cup the edges of the SS screen. It also is

held across the bottom edge with a channel formed in the base

sections. These SS screens are not just loosely set in these

channels. They are fastened in with hundreds of copper rivets,

so they also become part of the structural integrity of these

units. They are already much more rigid.

|

|

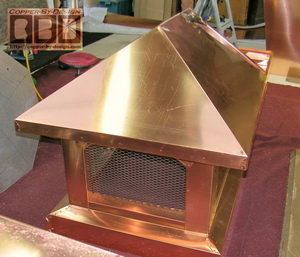

Then the eaves are made and attached over the

corner columns and cup the top edges of these SS screens and

riveted into place, which adds a lot more strength to these

structures. I also added a few SS screws at the corners.

Then there's the roof support braces to make

and attach with copper rivets. I believe this is a

very important detail that is not done by most any other sheet

metal shop, from what I've seen. I know they may get a lot of snow

there in New York, so these roof support braces are only about

8" apart for uncompromised strength.

|

|

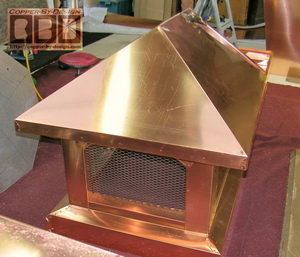

Then after a couple weeks work on these they were

finally ready for the copper roof skins to slide over these braces and

cup under the eaves. It is very tricky to make this roof

skin in just 2 pieces for a nearly seamless construction. They

are still riveted down to the roof braces to help keep them from

rattling in the wind.

|

|

This is the crate I built to carry them safely

on their journey across the Country. The larger chimney cap is

not resting on the smaller one. There is cross boards under to

suspend it over the other cap. I also made a 1/4" thick plywood

shield over the smaller cap's roof just incase something came

loose, or just from bouncing on the roads.

The crate weighed almost as much as

the contents. It is 40" wide X 60" long X 68" tall and weighed

around 375# in all.

|

|

I got the separate weights as I worked on

these while taking these digital photos to share with the

clients most every night for their review as the progress

continued:

Larger Chimney Cap:

-

30.4# -

Base and Columns = 24.32 sq'

7.2# - SS screens = 12.06

sq' X $20 = $241.20

9.4# - Arches = 7.52 sq'

6.8# - End eaves = 5.44 sq'

7.6# - Long side eaves = 6.06 sq'

8# - Roof Support

Braces = 6.4 sq'

30.4# - Roof Skin = 24.32 sq'

99.8#

total weight

92.6# copper = 74.08 sq' X $25 = $1,852

$2,093.20

sub total

Smaller Chimney Cap:

-

26.8# - Base & Columns = 21.44 sq'

5.6# - SS screens

= 9.53 sq' X $20 = $190.60

7.2# - Arches = 5.76 sq'

6.8# - End Eaves = 5.44 sq'

11.2# - Long Side Eaves & Roof Support Braces = 8.96 sq'

21.2# - Roof Skin = 6.4 sq'

78.8# total weight

73.2# copper = 58.56 sq' X $25 = $1,464

$1,654.60

sub total

$2,093.20

-

larger cap

+ $1,654.60

- smaller cap

+ $450

- for the crate

+ $400

-

for truck freight shipping to residential w/lift-gate

service

= $4,597.80

Grand Total

- $2,820

paid

= $1,777.80

balance due before they shipped

|

|

These were the photos sent to us by the client showing

the installation.

From: "Edward Peabody"

<peabodye@westelcom.c*m>

Subject: Chimney Caps Installation

Date: Mon, 12 Apr 2010

We had the chimney caps installed today. The large one went great, and the other took some extra effort because the cement cap Had a curve on one side. Glad you sent the spare nut and bolt sets, because the guys dropped several pieces. We think they look terrific. Here are some of the photos I took. Thanks again for the great job.

|