|

We made this a set of

2 chimney caps and a matching lighted cupola that are designed after

our Tuscan arched style 4 column w/screened exhaust vents. These

were for our client named Scott Matovich in Setauket, New York,

who had been patiently waiting around 6 months for us to begin his

project.

In the Winter of 2010 a large tree was

knocked over in a storm and hit the larger chimney cap seen

here, so I've been asked to rebuild it with the improvements

I've made since this was first made. One noticeable option will

be to make the longer sides with a double arch design, instead

of this one long arch. This way the end arches will match more

closely to the sides. I would also like to lower the roof a bit,

so it's not quite as high up over the arches.

I shared 150 of these digital photos

you'll see below during

the construction process with this client through e-mail. I doubt

there are any other shops who would do this.

|

|

Stage 1:

Working the Deal

The client shared several

good clear photos with me, so I had a good picture of what these

chimney caps will be mounting on. They need to have a sturdy

mount to withstand high winds and also be removable for servicing

or flue cleaning.

This is his pool house that he wanted a matching

copper cupola with a soft light inside and a flood light for late

night clean-up. We were able to work up a quote that was agreeable

for both parties with only a couple e-mails on 4/17/06.

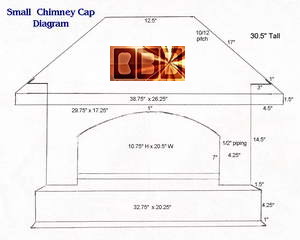

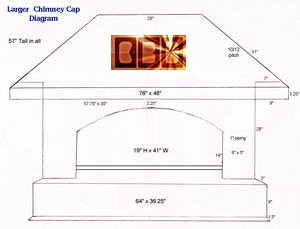

There is a lot of tricky

math that goes into these fabrications. I had to mathematically

scale each unit to be proportional to the Silbernagel cap in order

to have the same sort of look. In general I divided those measurements

by 1.4 to reach just the right proportions for this smaller chimney

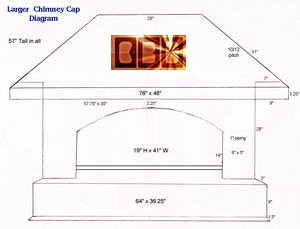

cap. The larger unit will needed a 64" x 36.25" base with a roof

that is 73.5" x 45.5". I needed to multiply the dimensions by 1.6

to reach the right proportions.

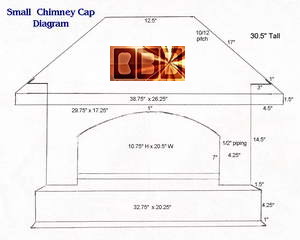

You can see the differences

here, even though the look is very similar. The smaller cap diagram

was scaled to 1cm = 2", where the larger cap diagram was drawn to

a 1cm = 3" scale. The reason I am so generous about the info we

supply on our web site is that we hope these do inspire a higher

quality work in other shops, but sadly there is not a lot who have

what it takes to benefit from this information.

These have a 10/12 pitch

hipped roof design to match their house roof, along with a thick

stainless steel screening set back behind columns. We also included

a custom angle cut wood frame for the larger chimney cap to rest

on, with the stainless steel mounting hardware, so it is secure,

yet removable for cleaning or other maintenance.

|

|

The Smaller

Chimney Cap Fabrication

|

|

Stage 2:

The Base

(10/11/06)

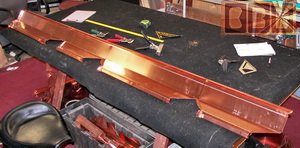

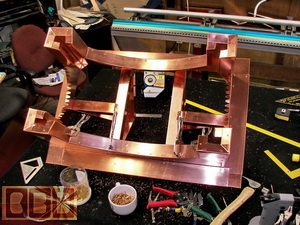

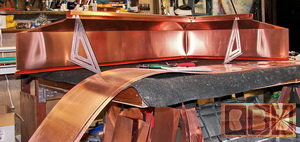

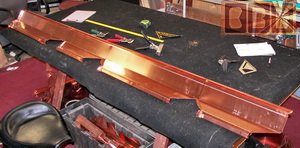

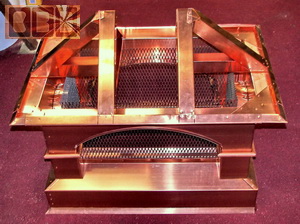

Beginning fabrication of the smaller chimney

cap . This one is over twice as long, which means it took

over 3.3 times as much metal to build to the same proportions. This

shows the base being formed with the stainless steel screen cage

set in the channel I made on the base.

|

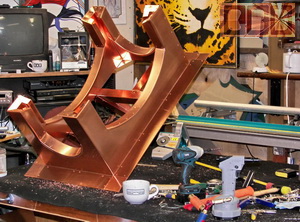

| Stage

3: Mid Arched Column Section

(10/13/06)

The fabrication of the arched column section. This shows the arched column frame being bade in one single piece.

The test fit was good.

|

|

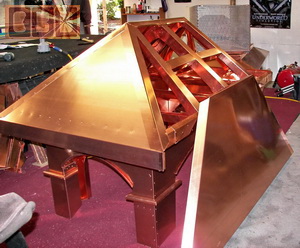

Stage 4:

Roof Framework (10/14/06)

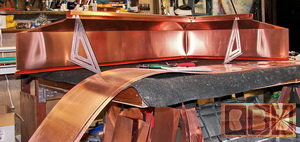

The corners of the soffit

need filled in and the roof bracing goes on. I built these

2" wide roof braces over that to support the roof panels from impacts

and snow loads that could occur. Once assembled it was structurally

solid feeling and does not seem to have any flex to it when lifted

up on one corner. I think this is the sturdiest chimney cap I have

made to date.

|

|

Stage 5:

Finishing Mid-section Details

& Attachment to the Base (10/16/06)

The arch frame needs

attached to the flanges between the columns.

Attaching the decorative piping on the columns

and fastening this to the base.

This shows the stainless

steel screen riveted under the roof bracing to make a fully enclosed

cage.

|

|

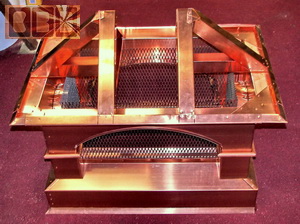

Stage 6:

Roof Cover (10/17/06)

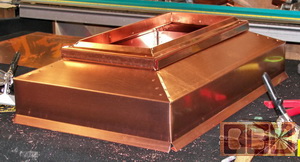

Then the 2 part roof skin goes over the bracing

and riveted in place.

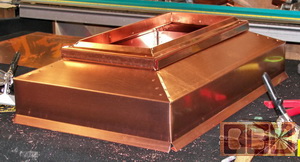

This is the small chimney

cap complete with a base rim of 32.75"long and 20.25" wide inside

measurements. The sides of the base are 4.25" tall plus the drip-edge

kick-out at the bottom. The arched frame that supports the roof

over the base you see below is 14.5" tall with 8" tall screened

vent openings that are 20.5" wide. If you look at the larger

images that these smaller images link to; you

can see the thin clear vinyl protective film on it covering the

outer shell of the 20oz copper we use. They will need to peel this

plastic film off after they install the chimney caps, so the copper

can tarnish as it should. The final weight was 66 pounds.

That equates to 48.48 square feet of copper and 8 square feet of

the SS screen.

|

|

$1,614.40 -

small chimney cap 48.48 sq' x $30 per sq' plus 8 sq' SS screen x

$20

|

|

The

Larger Chimney

Cap Fabrication

|

| Stage

7: The Wood Saddle

(10/19/06)

I first had to build this frame to set the copper base on while

I work on it. This was made with 5/4" x 6 pre-primed fascia boards

glued and screwed together. Then I had to angle cut the top to match

the angel of the copper chimney cap base section.

|

|

Stage 8:

The Copper Base & Center Pan

(10/11/06)

Here is the first 2 sides of the copper base

being formed in one piece, folded, and sealed. Then set on the wood

saddle that is suspended up off the floor.

Here is the first other 2 sides of the copper

base attached to the first part and sealed together. Then the center

pan is made to cover the middle with a channel for the stainless

steel spark arrest screen to set in around the edge of this pan.

I bent this big X in the middle of the pan to help raise it up in

the center, so the splashing rain will drain out to the sides.

|

|

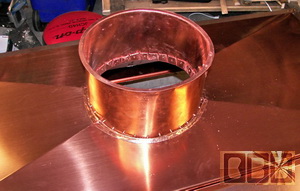

Stage 9:

The Stainless Steel Spark Arrest Cage

(10/20/06)

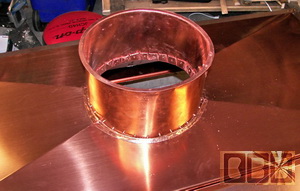

Here is the base with a pan built inside so the driving rain

cannot get in. There is a channel around this pan for the

stainless steel screening to set in. I made an entire 5 sided

stainless steel screen cage for over the pan. This is a high grade

stainless steel that will not attract a magnet, so that means there

is no iron in it to rust. It is noticeably harder to cut and drill

than copper or steel. We have to use a special 10lb electric Bosch

shear just to cut it. That tool cost $650 alone. I built the

long sides and top all in one piece for the best possible strength.

Then attached the end pieces.

Then the flue hole gets cut and the collar

gets attached and sealed to the pan.

|

|

Stage 10:

The Mid Arched Column Section

(10/21/06)

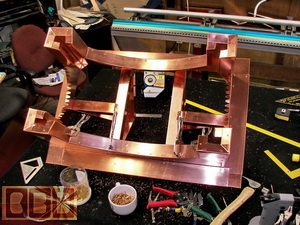

I began to build the mid column section. I was crazy enough

to build 3 sides all in one piece for the best possible strength

and seamless look on one side of this chimney cap. Then attached

the back piece.

This shows the frame

being attached to the undersides of the arches between the columns.

Here it is up on one

end with all the corner soffits in. Then the piping goes on

the columns.

|

|

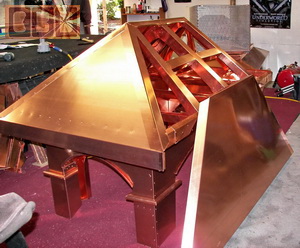

Stage 11:

The Roof Framework (10/23/06)

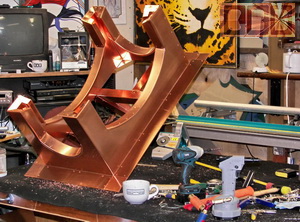

These photos below shows the much more elaborate

3" wide roof bracing for this larger unit. The braces here take

a sheet of copper that is as much as 9" wide.

When I got these braces fastened on it was amazing how rigid this

mid section became. I could lift it up by on corner and have hardly

any flex. It seems I had still drastically under bid this job.

This added so much more

copper than originally predicted. I had based the quote on how much

copper the Silbernagle chimney cap had used. Not factoring the bracing

under the roof, and I had not gotten the roof pitch of the house

until the day I was to draw up the final diagrams and begin construction.

The Silbernagle chimney cap had only a 6/12 pitch roof, where this

client is getting them with 10/12 pitch roofs. Fortunately for me

Mr. Matovich was understanding and offered another $1k to cover

these changes, but he still was getting about $1,000 worth of free

copper and stainless steel screen in this one unit alone, for this

$4,650 chimney cap.

|

|

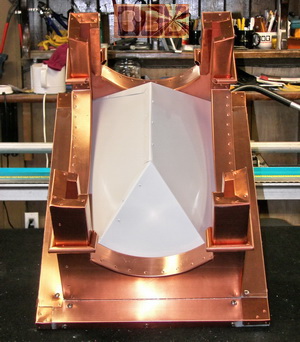

Stage 11:

The Roof Skin (10/27/06)

Then the 4 part roof skin goes over this bracing

and riveted in place.

|

|

Stage 11:

The Top is Fastened to the Base

(11/2/06)

Here The top ready to get attached to the

base. You can see here I added a brace on both sides of the flue

hole under the pan to help support it from possibly sagging in the

middle. I want to be sure there is no water puddling on the

pan.

|

|

|

|

|

Stage 12:

Building this Large Crate

(11/5/06)

I used 1x3 and 2x3 boards

for this crate frame with all the screw holes pre-drilled, so the

boards would not split. I also glued them together as I set the

screws. The chip board was then glued and nailed to this frame.

I later came to realize that even though the 1/4" hardwood plywood

may be twice the cost, it is worth it in the savings of crate weight.

The shipping charges are more for the heavier wood than the cost

difference of the lighter harder crate shell.

I used about 162.75

square feet of copper plus 27.9 square feet of the SS screening,

compared to the total of 130 sq' we had estimated. I later got the

final measurements that were a good deal larger than the first set

of numbers. That is 60.48 square feet more than in the original

quote. This is a good example of how we refuse to short cut quality

even when we are not getting paid enough for the amount of materials

that go into a project. Strength is paramount to us. This unit weighs

a total of around 230 pounds in all, not including the weight of

the wood frame the chimney cap will be resting on.

$5,440.50

- large chimney cap 162.75 sq' x $30 per sq', plus 27.9 sq'

SS screen x $20

This project has already taken over

3 weeks so far.

|

|

The

Matching Cupola w/Lights & Weathervane

Mount

|

|

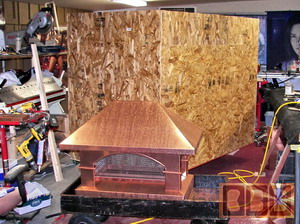

Stage 13:

Building the Cupola (11/16/06)

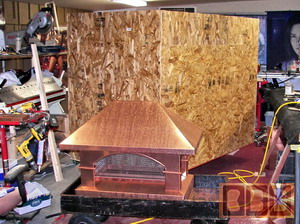

This one is just a couple inches smaller than

the small chimney cap shown above, but taller with the longer base

skirt to match the roof angle to sit on the roof ridge. I had to

rig up a weathervane mount in this roof structure. This right shot

shows the 3 layer 1x4 Poplar hardwood brace I made in the middle

to hold the bottom of the support pipe. It has a cherry stain over

it.

|

|

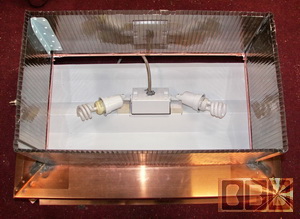

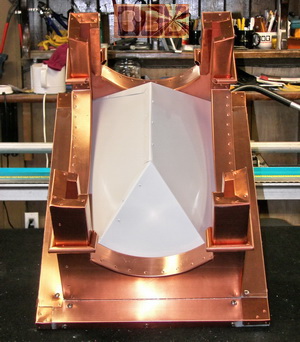

Stage 14:

Figuring Out the Lighting & Wiring

(11/20/06)

I needed to experiment for a while with several

different systems to see what would work best. I ended up using

a set of 2 bulbs that reflected off a shield above and a larger

reflector below in the base. I also made a third white reflector

up in the center of the cupola.

I tried a 12" stainless steel pyramid inside

as a reflector, but that was not giving me the look I was after.

I finally went with a white pre-painted aluminum to use as the reflector

lit from in side the base, so the light bulbs would not be seen.

I then had to rig up a security flood light in the base with limited

space.

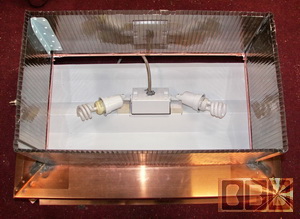

In the left shot you can see the pair of florescent

bulbs down in the base over a white aluminum reflector. The

right shot is from under the base, where I added a set of oval reflectors

on a sheet of clear polycarbonate plastic to go over the light bulbs,

so they would not be shining up directly on the reflector making

extra bright spots down low.

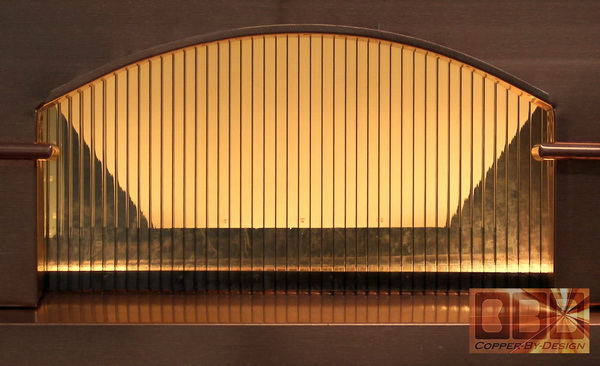

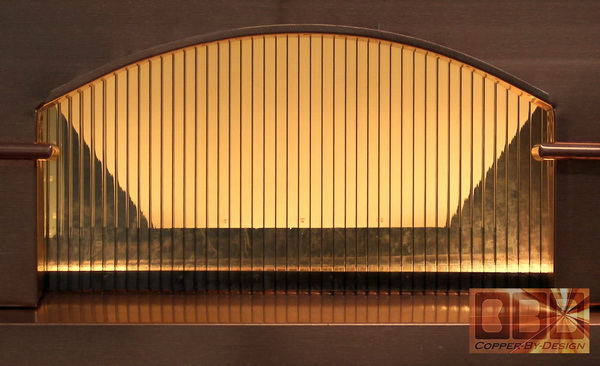

As you can see here I finally

achieved a nice soft even glow on the upper reflector inside.

|

|

Stage 15:

This is Finally Finished

(11/30/06)

This small project took me longer to build

than the larger chimney cap above. I had to do something a

bit different to work out a soft glowing light inside, where the

hardware would not be seen from outside in the days time, so I used

the tinted polycarbonate plastic to hide it. It think it turned

out pretty well.

|

|

Stage

16: Crated Up & Ready to Go

(12/1/06) Stage

16: Crated Up & Ready to Go

(12/1/06)

I boxed up the small chimney cap and cupola

in the same crate, since they were so similar in size. I had flat

sheets of Styrofoam between them so as not to scratch or dent each

other while bouncing down the road.

I have to make sure the crates are very strong,

since the trucking company will probably be stacking other boxes

on top of these.

|

|

The final measure for both of these chimney

caps was 316.44 square feet, which was 101.44 square feet over the

estimated amount. That means they got $1,528.40 in free fabrication

work. For both this and the Gross chimney cap bids (shown above)

I had based the estimate on the copper used in the Silbernagel cap

and multiplied that by how much larger or smaller these caps were

to be. My mistake was how I did not take into consideration: (a)

the extra height they would need to be, to be in the same proportions.

(b) the steeper roof pitch. (c) and the need for cross bracing under

the roof skin for such large caps. I had no bracing inside the Silbernagel

cap since it was small and had not heat exhaust issue.

$1,614.40 - small chimney cap 48.48 sq' x $30 per sq' plus 8 sq' SS screen x $20

$5,440.50 - large chimney cap 162.75 sq' x $30 per sq', plus 27.9 sq' SS screen x $20

$2,028.75 - lighted cupola 46.25 sq' copper x $25, 11.5 sq' aluminum x $15, weathervane support pipe $125,

------------------------wood frameworks in base$100, wood in the roof$150, electronics $200, and tinted windows $125

$ 244.75 - wood base frames 45.5 board' x $5.5'

$ 400.00 - large crate

$ 300.00 - smaller crate

$10,028.40 grand total

Total cost for

this 3 unit project: $8,500

$1,528.40 savings from the actual

copper that went into these

The client handled shipping costs

through his account

|

|

Stage 17:

They are Installed & We Have Pics to Show

(3/7/07)

David - I will certainly send you

some photos, after install. It has been a pleasure

to work with you - thanks for all the good communication

and support. I trust the install should go well and we can

contact you if any questions....

Take care....Scott

Hello David,

They are finally installed and look

great. Their were a few small "bumps in the road"

during install, but the GC resolved them quickly.

I will get a few photos and send to you, as we just finished

some of the stone and trim work, so all is done.

Scott

|