|

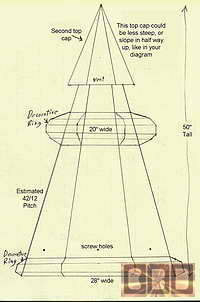

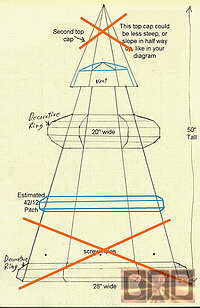

We were contracted to recreate a

large roof cap for a, in Chicago, Illinois.

We received these photos of their old rusty steel cap to try

and recreate it for them in copper. We gave them prices on fabricating

it just like the old roof cap, and a price for not adding quite this

much ornate detail.

They opted for the less expensive version.

We were happy to oblige them. Our aim is not to sell clients on the

most expensive roof cap. We try to keep our primary focus on offering

options for a good balance of cost and looks. We want each client to

feel they get a good product for a reasonable price they can afford.

36" tall

42/12 pitch

13" wide top cap

20" wide middle

ring

27" wide bottom ring

24"

inside width base

cost was $700 php

|

|

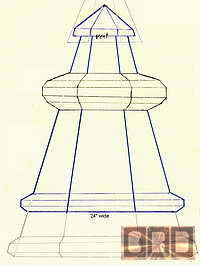

We could have designed and fabricated it just like

the original, but we had to bid it for over $1,000 to do this to cover

nearly the whole week time it would take to create it. We were asked

if we could make the new one at a reduced cost of $700 by making it

same size, but less soft curves to it and not as detailed. So

the photos below show what we were able to provide, after exchanging

several diagrams for approval.

|

|

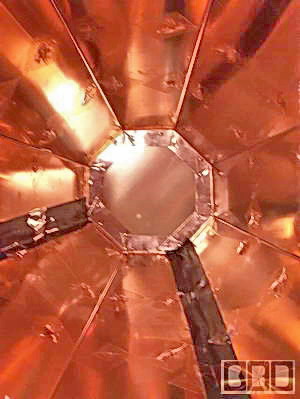

This is the main roof the cap

sections drawn out and then cut out of the large copper sheet.

This may not be the most practical use of copper sheet metal, but it

will be much less likely to develop a leak, and it is much stronger

this way.

The sheet of copper shown above

is 10' long and 3 feet wide. It still has the clear plastic film over

one side that will be used for the outside of this copper roof cap to

protect it from finger prints, which would make an uneven tarnished

look. It shows the template for one of the 8 sides that we made

from the dimensions given for this cap. Because of the large size

of this caps main section; we could not make it in one piece like we

normally try to do, so we had to cut the other 2 sides out in a separate

piece.

|

|

Here are the two pieces of the main cap section formed

into the proper shape. This section will have the seams set to

the back of the house, so there will be no seams on the front.

These photo show the sides bent to form the cone

cap shape getting sealed and riveted together

in this cone shape, showing the 2 seams we need to seal.

|

|

Here is pictures of the bottom rim being made

and installed. The 5.25" wide strip was 88.5" long. We used 62 rivets

to attach it.

This

is clearly the strongest bottom edge we have made to date. It is so

stable, it will be difficult to make any adjustments due to any irregularities

there may be to the roof top. We later used a clear caulk to seal

the top edge of this decorative rim to help keep water from getting

trapped inside this rim. This

is clearly the strongest bottom edge we have made to date. It is so

stable, it will be difficult to make any adjustments due to any irregularities

there may be to the roof top. We later used a clear caulk to seal

the top edge of this decorative rim to help keep water from getting

trapped inside this rim.

Again, it still has a clear plastic film over the

bare copper to help keep finger prints off of the copper. The

oil from finger prints causes early tarnishing and makes it tarnish

in a rather spotty manner. The plastic film will be pealed off

after the final installation.

|

|

Here is the large decorative ring being fabricated from a strip

of copper that is 12" wide x 67.5" long. The math involved with

this part was one of the most challenging parts of our work. Not

only that, but we first have to visualize this in our mind in a 3 dimensional

way to get the ideas for the math we need to figure out. We used

80 rivets to connect this and attach it firmly to the cap

|

|

Here is the small top cap going on this roof cap.

We do everything we can to hide the rivets when possible. It was not

easy to rivet the top on from inside, but it was the right thing to

do. We are not people to shy away from a challenge.

|

|

Here is the the custom wood framed crate we made

for this turret roof cap. Our 4 year old son below left gives you a

good idea of how large it is, but it will look plenty small once it

is installed. The last photo shows it with most of the cardboard stapled

over the wood frame. Luckily we have a DHL distribution center not far

from our shop, so I always run these down as soon as I have them ready

to ship.

|