|

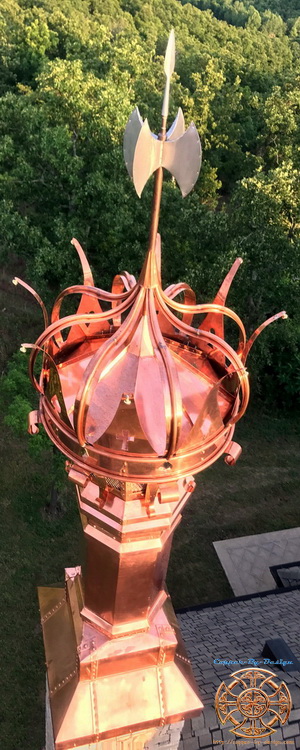

Adding a Decorative Touch

(intro):

Some clients think of this

as the crowning

jewel on their house; built to last a century or more as an heirloom

quality product. It is a solid investment in

precious metals. These may seem rather expensive, but compared to the

cost of a nice gold ring (which could easily get lost) these are a

bargain for what all goes into the personal design and workmanship

involved. Keep in

mind that most of the cost is design, labor, freight, and

installation, so using a thinner copper is unwise. Especially when

a slight graduation in the thickness of copper gets expidetially stronger.

Better Quality with Thicker

Copper:

Below are examples of the custom sheet metal chimney caps built by

CBD over the last 25 years. These are made with 99.9% pure copper,

copper rivets, a high grade non-magnetic stainless steel spark

arrest screen and screws. These chimney cap shells are built with a

thicker 20oz, 24oz, 32oz, and some 48oz thicknesses parts. The thickness of

copper is based on it's weight per square foot, so the higher the

number the thicker the copper is.

We have not used any 16oz copper in any of our

projects for well over 20 years. CBD does not even use that standard 16oz

copper for roof flashing. Yet, since most clients do not know the

difference that thinner 16oz copper is still

primarily used by

most other sheet metal shops; whom are even willing to work with copper

at all. This is a very important detail when considering quotes from

other shops. Imagine twice as strong for just a 25% added cost.

If you have an oportunity to feel these different copper thicknesses I

highly encourage you to do so. I can mail you a set of samples for

$100 minimum charge, which can be applied toward the cost of a project you have us

build for you.

Here is an example of the difference in strength

between these thicknesses:

16oz copper -V- 20oz copper is only

25% thicker, yet is 50% stronger.

16oz -V- 24oz is 50%

thicker, but feels over twice as strong.

16oz -V- 32oz is just twice as

thick, yet at least 4X stronger.

16oz -V- 48oz is 3X thicker

and strong enough to stand on.

As sturdy as the 1/2" plywood on

your roof at just 1/16" thick.

Our current base rate for a chimney cap design/fabrication w/o crate

or freight is:

$35 per pound

for copper; regardless of the thickness

$25 per square foot for the

heavy duty 13ga SS screen we use

$18 per linear foot for the 5/4X6

hardwood used inside the base skirt

A separate

charge is added for extra complex, ornate, and curved

fabrication details you may want implimented.

Over the last 2 decades of building custom copper chimney caps CBD

places our focus on many details not found with other shops at any

price. This has been a gradual process I have refined over that

time. The biggest mistake most shops still make is soldering copper

pieces together. This should never be done because solder melts at just 450 degrees, or

just oven

temperature. Solder should not be relied on for holding a chimney

cap together. Especially since aluminum at a melting temp of 1,200 degrees is not suitable for a wood burning chimney.

Where copper is rated at 2,000 degrees. In stead, I build

these chimney caps with overlapping seams that are riveted, screwed,

and or bolted together. More like aircraft construction. We are

not making tea pots here.

In Fall of 2017 I got

in my first large shipment in of thicker 24oz copper sheet stock to use for

most chimney cap projects since then. This is to replace the thinner 20oz copper I had

been using, which was more than what most sheet metal shops are

using. We had a few large chimney caps get damaged in transit,

so I felt the

need to increase the strength, which will also lay flatter; for a less

bucked and wavy look across large flat surfaces. Such as the copper

roof skin. This 24oz copper at just 20% thicker than 20oz copper may

not seem like a lot more. Yet, it adds about 33% more strength or

stiffness and dent resistance of these fabrication at just 15% added

cost. This

will add a bit to the weight, which is good for wind resistance. The majority of what these projects cost is

design, labor, packaging,

and freight. The minor cost increase for better materials is your

wisest investment with any custom project like these.

The most important advantages of our service may not seen as much from the outside.

Here is a list of advantages we impliment, which you are not having to ask for

or pay extra with a CBD

fabrication:

-

2X stronger copper than industry standard. We faised out 20oz

copper in medium to large size chimney caps for an even thicker 24oz

copper sheet stock as of

10/17 for use

as our standard thickness

(unless requested otherwise by the Client).

-

Designed with a more subtrantial 3 dimentional shape for a distictive look from

a distance, which also makes

these a much sturdier construction as well.

-

A more seamless design for a better looking and stronger

fabrication, with fewer visible SS screws and rivets.

-

Built weather tight w/o caulk or solder,

since those sealers can not handle the high heat of a

chimney flue exhaust. Solder is not even suitable for a low temp natural gas flue;

where aluminum is commonly used. Copper or stainless steel is necessary for all other

forms of exhaust; rated at 2,000 degrees.

(question: how does this basic logic

escape other sheet metal shops willing to work with copper?)

-

Built with an endoskeleton framework.

As opposed to an exoskeleton, or

standing seam design commonly seen. This offers a cleaner look

and less debris traps. No visible bones of the

structure is our goal. (most

other shops do not impliment any roof bracing support).

-

A much stronger 13ga flattened

expanded high grade stainless steel spark arrest screen, which adds a

good deal of structural strength to these hollow structures. The spark arrest screen is usually deep set into the corner columns under the roof cover ledge.

(not flush like other shops

tend to make). A rabid raccoon would not be able to claw or chew through this screen.

Even tin snips would break trying to cut this screen.

-

An

easier yet sturdier attachment, including a set of custom lift boards

roped together ready to use for a smooth installation.

(a feature you

will not get from other shops at any price).

-

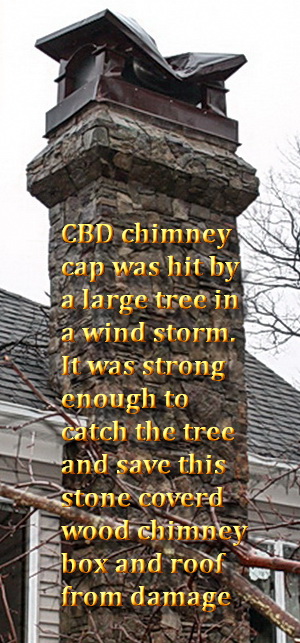

And one of the most important details is the dense hardwood used inside the

2X taller base/skirt for better attachment and more base weight

for stability in wind storms. This is to reduce the risk of these expensive cover

smashed on the ground after a wind storm and the damage it could

cause to what ever or whom ever it hits.

-

We also build the sturdiest shipping crates you are likely to

have seen: a plywood cover glued and screwed to a solid

wood framework. We do not even use cheap chip-board for

disposable shipping

crates. We also add thick foam cushion padding for shock

resistance.

-

We include the fastening hardware and detailed installation instructions

customized to your situation, and offer phone consultation

during installation at no extra charge.

Long Term & Short Term Value:

Like with an investments in

gold; copper is also a rock solid investment in a valuable metal not subject to

depriciation. Like with the rapid depriciation of your savings

account. Or worse: a new automobile purchase, which is worth half of

what you paid before you have it paid off. Some Homeowners may see these

fancy chimney caps as a bit pricy. Although,

this same person would not scoff

at paying an extra $5k for upgrades to special rims and running

boards on a new SUV. Is this not a more lasting value up there as the crowning jewel on your home? Copper

cost us us 5X more than the aluminum those rims were made of, which were

not even custom hand made, let alone a unique original design. Your house is not likely to depriciate much at all,

as long as you keep it up in good shape.

Clearly CBD is the best value for all we put

into each project. Unlike other speed-shops a single CBD fabrication typicaly takes a couple weeks

to a couple months for us to produce.

Listed on these web pages I've also taken the time to provided

you with far more

information here than you'll find

on any other web site of this nature, so that you can anonymously shop

prices before contacting CBD. Each photo links to a full screen

image for a better look, or it links to a more detailed web page with

many more

related photos

from that project with a detailed description of that project. Many with

step-by-step photos, which you are not likely to see on any

other sheet metal shop web site. This helps you compare prices and give you ideas for a personalized quote

w/o having contacted CBD yet. Risking to suffer through a high pressure sales scheme,

as you have found on most other web sites w/o any prices listed.

There are several of our most popular Tuscan

arch style chimney caps shown below, which may looks the same, but

they are each unique and have different size bases to give you a

better idea of what it may cost for your home. The roof may be wider

than the base, or numerous other details that are different for you

to choose from. They tend to range in price from $200

to $400 per linear foot measure surrounding your chimney. This depends on

factors of: internal pan, ornamentation,

and if we need to ship this across the Nation in a sturdy wood

crate.

Unlike other shops we are all about custom

fabrications, so we do not offer a discounted cost for

just copying a previous design. Custom deigns are our specialty, so

don't me shy to ask us for something unique and special. Our Clients placing

faith in our ability is what has allowed CBD to offer such a wide

variety of examples shown on this web site of ours.

You may also find our chimney flashing kits beneficial:

http://copper-by-design.com/cc/cf.htm#kits

Note:

We do not intend to be misleading with prices listed on projects made prior to to mid 2006.

Back when copper was 1/2 the cost it is now, so each project is

clearly dated and sorted with the latest project at the top and

progressively older as you scroll down. I recently added the cost

for each project buy the linear foot surrounding the chimney top. Keep in mind the prices listed were just

the amount those clients had paid

at that time made with a thinner copper, so current prices may not be that low

after we had upgraded the copper used from 20oz copper to a

thicker 24oz. You can go to our

Latest News web page to read more on

this subject.

|