|

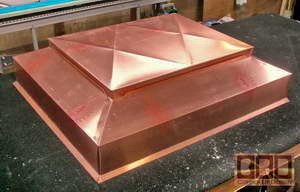

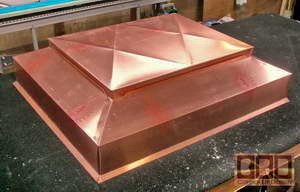

The detailed custom fabrication of a 33.5" wide x 39.5"

long copper chimney cap

(1-06) |

| Here is what we made with the design help from

the client: Todd Silbernagel in Dundee Oregon, just Southwest of Portland

Oregon. It was designed to cover a wood frame chimney case that was

covered with a stucco facing, and designed to support the aluminum bathroom

exhaust and plumbing vent. There is not going to be any heat involved.

This was just the best way to not have lots of small pipes coming out

of their tile roof.

It took about 65.2 square feet of copper to make

this chimney cap, and weighs in at 81lb plus 24lb for the lower wood

base frame, and another 6lb for the upper wood frame to screw the roof

onto. Even though it has very few visible rivets it is so sturdy

that when lifting it up on one corner it seems to have no detectible

flex to it. Made as seamless as possible. This chimney cap sits

down to cover the top 2" thick wood frame that was screwed into the

studs and another 4" of the stucco facing over the wood. It took

5 to 6 full days just to build this cap in our shop.

The final cost delivered

and installed was $2,030,

See below

for the 60 other photos of this custom fabrication.

|

| The chimney top edge was just vertical studs,

plywood and stucco. This shows the wood base frame that will be screwed

down to the top edge of that chimney box and the chimney cap will be

sitting on. It is made from a set of 8 alternating boards that

are pre-primed 5/4 x 6. It was glued together with Gorilla clue and

held together with a couple dozen screws. Then angle cut to the pitch

of the copper base seen below.

|

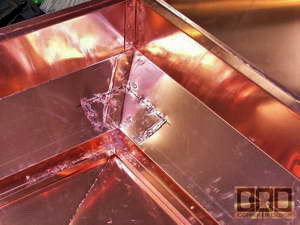

| The cap angles need to

be carefully calculated so there are no errors or unexpected complications.

We have to think several steps ahead, like working out the problems

of a Rubixs Cube. If we are in error, we may ruin some very costly

copper material. This shows three sides of the base bent

longwise, and then having the corners formed.

The lower section design has been drawn out on the copper on both the

film side and the underside, since there are several bends and cuts

to be made in both direction.

Our work table is 4' x 8'.

The sheet of copper shown come 10' long and 3 feet wide. Keep in mind

that the copper sheet metal still has a protective clear plastic film

over one side that will be used for the outside of this copper chimney

cap to protect it from finger prints and scratches. The red print will

come off with that film. It is to be pealed off after installation.

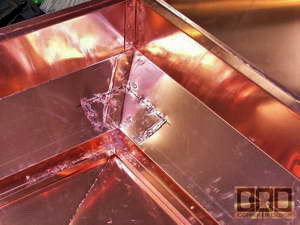

It is careful work to bend and fasten the corners here so they are perfect

right angles before riveting them together. The cuts in the inside

of the corners are also tricky to calculate so it will fit together

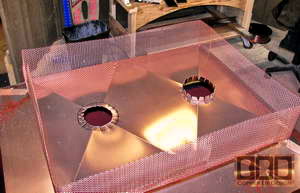

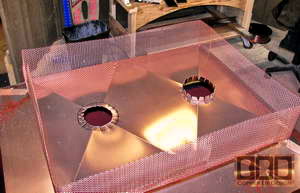

just right. Here is the base section getting the flue pan secured

in place.

This pan has to support two separate vents and be able to seal

out hard blowing rain, and shed that rain out to the sides. I

have made this with a pair of cross bends to raise the centers where

the vents will go up through the copper pan. I also made a channel for

the copper screen to seat into.

We then cut the tabs to bend up that will be clamped against the

flue pipe. with this copper straps and the stainless steel bolts with

lock nuts. In the last photo I had pealed off the protective film off

the pan. That is why it looks different.

|

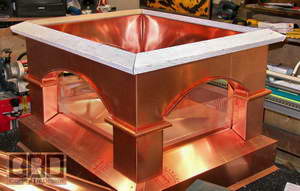

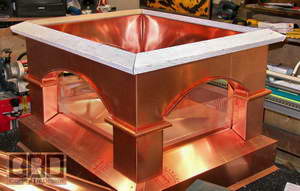

The middle section body of this cap that will support the roof is

one piece for all 4 sides (as seen here), with only one seam.

It is only 15" high. We then seamed the frame together with a

pair of 1" overlapping seams over the back corner.

|

|

Here is the middle section frame standing up to finish

riveting the arch wells in place.

|

|

This is the assembly of the roof frame to go over

the arched screened area. It was made in only 2 separate section and

sealed together with overlapping seams.

|

|

This shows the corner piping trim mounted just

below the arches over all 4 sides of each corner post. Since there is

no heat involved with this chimney cap, we made another custom wood

frame to secure to the middle section and screw the roof onto. Allowing

for easy removal for future maintenance.

|

|

This shows the two different angled wood frames

we made for just under the roof and under the base.

|

|

This shows the vent holed we cut into the copper pan and bent

the flanges down for the clamps. I am attaching the middle section to

the base and sealing the corners with a clear caulk.

|

|

This is showing the screens area bent into shape

over the arches and attached securely with rivets to keep out any pests.

|

|

Here is some detail shots of this chimney cap

in daylight of the finished chimney cap from several different angles

to get a good look at it. It is not perfect at close inspection, but

the client said it turned out better than he had imagined. That is one

of the best compliments we could get. Our main focus is to make it durable.

|

|

The roof of the house has clay tile roof, so the

owner wanted to minimize the pipe vents needing the punch through the

roof, so he organized all the pipe vents and house vents from the bathrooms

and kitchen to connect in the center and go up through this one area

in the top of the roof. Then contracted us to make this nice vented

screened roof cap.

|

|

Here is the chimney box from up on the roof as

we show the installation. The flashing just over the roof is copper

as well, and shows the tarnish from just a few months.

The first step was to try an level off the stucco

using a chisel. The stud placements were measured for the drilling of

the screw holes in the base frame. Then attach the base frame to the

top with long 3.5" deck screws you will see in the first photo sticking

up out of the wood.

They fitted the vent pipes up through the pan

after we had it secured in place. Then caulk the pan and secure the

pipes with the collar I made with the stainless steel bolt.

The black plastic pipe was trimmed a little lower

before the roof was installed and screwed down tight and the plastic

film finally pealed off.

|

|

Here is more photos of the house with the finished

copper chimney cap in place

Here is their splendid view from the back of the

house.

|